Batching from empty, Coriolis research, Advanced Instrumentation Research Group

Batching from empty

There are many processes where the high accuracy and direct mass-flow measurement provided by Coriolis technology would be beneficial in the metering of batches. In many cases, however, it is not practical to ensure that the flowmeter remains constantly full of fluid. However, large errors may be induced in Coriolis meters when partially filled, or empty with wet flowtube walls. Hydraulic shock from the onset of flow, or a surge of air, may result in large measurement errors and stalling. Most Coriolis manufacturers are thus unable to recommend the use of their products in batch applications unless the flowtube can be kept full. At least one major Coriolis user puts the ability to batch from empty as the most important development required of Coriolis manufacturers [1].

The Invensys UTC transmitter has been designed to be robust to the conditions experienced when batching to/from empty, as discussed here. As the flowtube control algorithm ensures that no settling time is needed between batches, it becomes feasible to use Coriolis meters in repeated short batch operations such as filling lines, without excluding entrained air. Industrial applications using the commercial version of transmitter for batching from empty are described in [2] and [3].

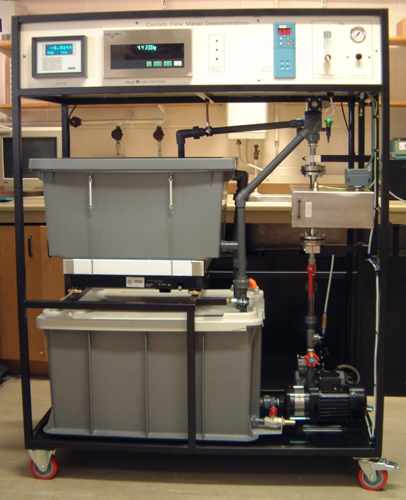

An interesting question is the relative repeatability of batching from empty vs. batching from full. Trials have taken place on a small demonstration rig (fig 1), using a 15mm flowtube, and a flowrate of 0.4 kg/s.

Fig 1. Rig for batching to and from an empty flowtube

For trials with the flowtubes kept full, a diverter system is used. With steady flow established, the diverter under transmitter control switches flow from a recirculation loop to a weigh scale. When the target totalized flow is reached, the diverter is switched back by the transmitter to the recirculation loop, and the finalized weighscale total is recorded. This procedure has the advantage of a more or less steady flowrate, but additional system non-repeatability is introduced by variations in the residual liquid retained in the pipework leading to the weighscale.

For the batching from empty trials the diverter is permanently switched to feeding the weighscale, and the transmitter controls the flow simply by switching the pump on and off. As the outlet pipe is open to the air, when the pump is switched off the Coriolis meter is drained by gravity, and so starts the next batch empty. At the start of a batch the flow total is zeroed and the pump is switched on. When the totalised flow reaches the specified target weight, the flow meter switches the pump off, and the finalized weighscale total is noted. This procedure has several sources of non-repeatability: the flowtube filling process itself, but also the diverter performance, and variations in how much fluid is retained in the pipes at the end of each batch.

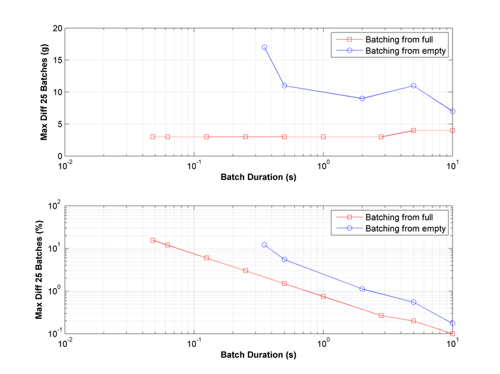

In each trial, the Coriolis transmitter was given a target weight based on a batch time at a flow rate of 0.4kg/s. Thus, for 10s batches the target weight was 4kg, while for 0.25s the target was 0.1kg. In the batching from empty trials, additional time was needed to increase flow from zero and indeed to fill the flowtube. Nevertheless the same target was used to allow comparisons. For each target weight, 25 consecutive trials were carried out, and the repeatability recorded, here defined as the maximum difference in total across all 25 trials. The results are shown in figure 2. The upper graph shows the absolute repeatability in grams, while the lower graph shows the relative repeatability as a percentage of the total batch weight.

Figure 2. Results for short batches with flowtube starting full and empty

For batching from full, the absolute repeatability is approximately constant at 3g down to batches as short as 48ms. As a percentage of batch total, this varies from 0.1% for a 10s batch up to nearly 20% for a 48ms batch. For batching from empty with trials 0.5s or longer the absolute repeatability remains below 15g; for shorter batches there is poorer performance. From a relative repeatability perspective, these results suggest that 1% repeatability can be obtained batching from empty for batch totals corresponding to 2s or more at the nominal flowrate.

These results are a function of the entire batching system, not merely the flowmeter, and are therefore only indicative of the performance that may be achieved. Nevertheless, for batch times of 10s or longer, it is reasonable to suggest that the slightly poorer repeatability (0.2% instead of 0.1%) is a price worth paying for the engineering convenience of batching from empty.

References

[1] Reizner, J. R:, Coriolis – The Almost Perfect Flow Meter. IEE Computing & Control Engineering, Vol. 14, Issue 4, pp 28-33, Aug 2003.

[2] Control Engineering Europe: ‘Breakthrough’ Coriolis meter allows filling machine to operate with exceptional precision, p8-9, June 2004.

[3] Henry, M.P.: Precision polyethelene batch processing. Control Magazine, July 2004.