Research at the Impact and Shock Mechanics Group, University of Oxford

Research

Our Research

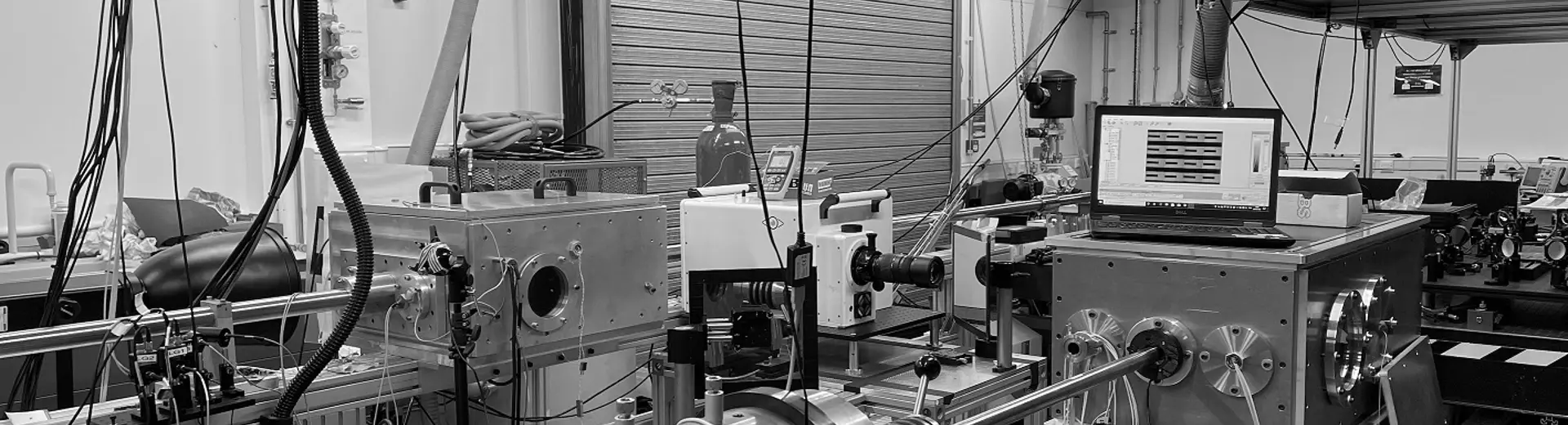

The study of dynamic material behaviour and structural response under extreme conditions has a long-standing history within the ISML Group, evolving from fundamental research in solid mechanics and impact mechanics. Current research, led by Prof. Dan Eakins (daniel.eakins@eng.ox.ac.uk), focuses on an integrated experimental-numerical approach to understanding the nonlinear response of materials and structures subjected to impact loading and other high-strain-rate conditions. The group specializes in designing and conducting bespoke experiments to observe and quantify deformation and failure mechanisms in a wide range of materials, from metals and composites to advanced cellular and protective materials. Utilizing high-speed diagnostics, including optical and X-ray imaging techniques, they capture the intricate details of material response under extreme loading. These insights contribute to developing improved predictive models and validating material constitutive laws, ultimately advancing the design of structures and components for aerospace, automotive, and defence applications. By combining state-of-the-art experimental techniques with physics-based modelling, the ISML Group plays a leading role in understanding and mitigating the effects of dynamic loading on engineering systems.

Dynamic Material Behaviour

Research of the dynamic behaviour of material

Dynamic behaviour of material

Experimental testing of structures across a wide range of strain rates — from quasi-static loading conditions to high-rate impact and shock scenarios. Our work aims to understand material and structural behaviour under extreme conditions, bridging the gap between slow, controlled deformation and dynamic, high-speed events. For inquiries and further details, please feel welcome to contact: David Chapman (david.chapman@eng.ox.ac.uk)

Gas Gun - Taylor Impact

Gas gun experiments are used to study material behaviour under controlled high-velocity impact and shock loading conditions.

Composites and Fracture

Composites and Fracture

Fracture Mechanics

Our lab investigates fracture mechanics and damage evolution in advanced materials, with a particular emphasis on composite structures and adhesive joints. We study crack initiation, propagation, and failure mechanisms under diverse loading conditions, combining experimental methods with numerical simulations to uncover the behaviour of structural components across length scales. This includes tailored testing of bonded interfaces, and composite architectures - such as unidirectional (UD), multidirectional (MD), and woven systems - to support the reliable design and performance assessment of advanced engineering structures subjected to demanding conditions, including impact and crash scenarios. For inquiries and further details, please feel welcome to contact: Maria Lissner (Maria.lissner@eng.ox.ac.uk)

Composites Impact

Our laboratory offers extensive experimental capabilities for characterizing material and structural behaviour under a wide range of loading conditions. These include quasi-static, high strain-rate, and impact testing, supported by advanced diagnostic techniques for measuring deformation, damage, and fracture evolution.

Composites Modelling

In parallel, we employ computational modelling and simulation to complement our experiments. Using finite element analysis and multiscale modelling, we investigate fracture processes, predict material response, and support the development high-performance structures.

Computational Mechanics

Modelling - Computational Mechanics

Research in computational mechanics focuses on developing numerical methods and computer simulations to study the behaviour of materials and structures under various physical conditions. It combines principles from mechanics, mathematics, and computer science to solve complex engineering problems efficiently and accurately. For inquiries and further details, please feel welcome to contact: Simone Falco (simone.falco@eng.ox.ac.uk)

Concurrent Multiscale Moddeling

Multi-Time Stepping Algorithm

- Method formulation and implementation

- Comparison against State-of-the-Art algorithms

Non-Matching Mesh Algorithms

- Method formulation and implementation

Modelling explosions

We research explosive and high-dynamic events using advanced simulations and controlled experiments. Numerical models capture shock waves, large deformations, and fragmentation, while experiments validate material response at high strain rates. This integrated approach improves predictive models and supports safer design and protective technologies.

Crystal Placticity

We conduct research in crystal plasticity modelling to understand the deformation and fracture mechanisms of materials at the microstructural level. By developing and applying crystal plasticity finite element methods (CPFEM), we investigate how microstructural features and crystallographic anisotropy influence material strength, damage, and failure.