10 Jan 2021

A novel integrated material recovery and waste-to-hydrogen concept

Dr Kok Siew Ng (University of Oxford) and Dr Anh Phan (Newcastle University) have recently published a paper entitled "Evaluating the Techno-economic Potential of an Integrated Material Recovery and Waste-to-Hydrogen System” in the Resources, Conservation and Recycling journal.

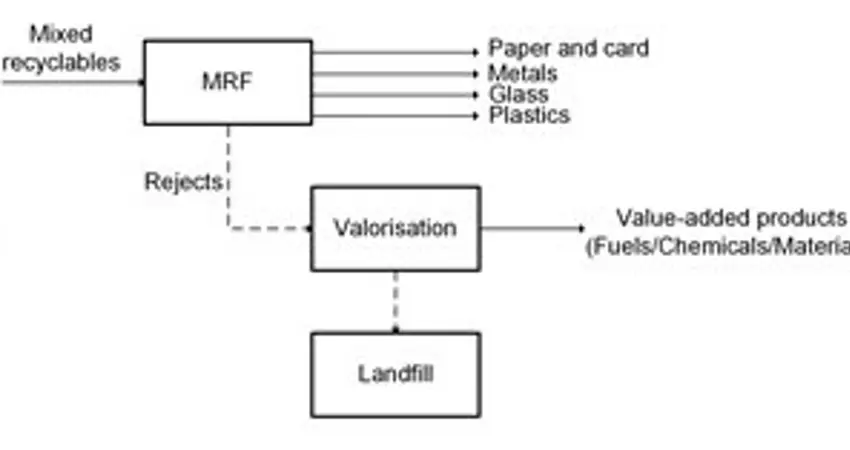

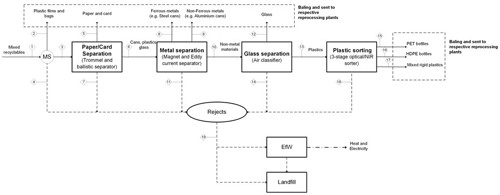

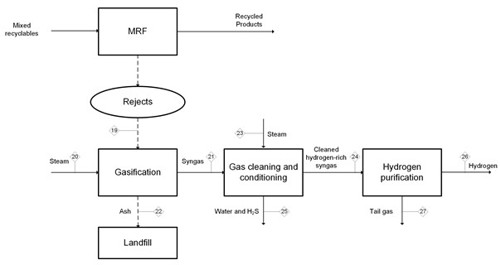

This study proposes a novel integrated material recovery and waste-to-hydrogen concept in view of enhancing resource efficiency and minimising environmental impact. A comprehensive techno-economic evaluation is conducted on an integrated system consisting of material recovery facility (MRF) and gasification of rejected materials for hydrogen production (Gasification-H2). Valorising these rejected materials through Gasification-H2 system can potentially offer a saving of 1.6 million £/y on disposal cost while diverting significant amount of waste from landfills. Owing to the high market value of hydrogen, the integrated system with material recovery and hydrogen production generates 4 times more revenues than a conventional MRF, though at the expense of higher capital and operating costs. The minimum hydrogen selling price lies in the range of 2.2 £/kg (100 dry t/h of rejects) and 6.1 £/kg (2 dry t/h of rejects). This study concludes that a larger Gasification-H2 system is desirable, i.e. greater than 100 dry t/h of rejects, to compete with the production cost of hydrogen generated from fossil-based systems. It is also recommended that an economically competitive production should comprise multiple MRF integrated with a large-scale Gasification-H2 system.

Highlights

- An integrated material recovery and waste valorisation concept is established.

- Integrated gasification offers a flexible pathway in enhancing resource efficiency.

- Low-value rejected materials can be valorised into hydrogen via gasification.

- Solid disposal cost can be avoided while creating additional revenue.

- Upscaling gasification system improves economic performance of hydrogen from waste.

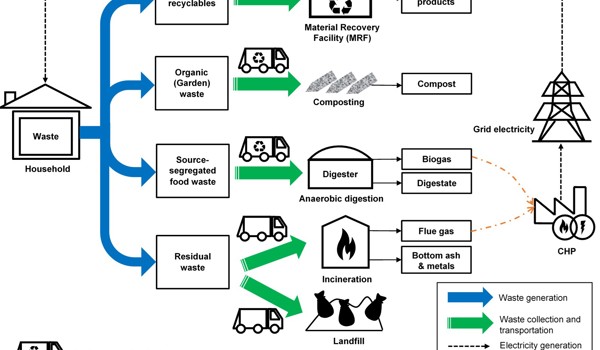

Material recovery facility (MRF)

Integrated MRF and Gasification-H2 System

The SYNERGORS Project

The SYNERGORS project (“A systems approach to synergistic utilisation of secondary organic streams”), funded by the Natural Environment Research Council (NERC), is led by Dr Kok Siew Ng from the Department of Engineering Science, University of Oxford. This project aims to develop new systems approaches and decision-making tools for promoting resource recovery from secondary organic waste streams including fossil- (e.g. used plastics) and biomass-derived waste (e.g. food waste, residual biomass).

SYNERGORS will provide significant insights into various options for organic waste reduction and utilisation, and propose viable business models to attract stakeholders in the commercial sectors to invest in these areas. Furthermore, the research will address various socio-environmental challenges faced by human and living communities, the rising global demands in energy and commodities, and lessening burdens on the landfill, water and atmosphere.

It is envisaged that the outcomes from this project (e.g. decision-making tool and roadmap) can be adopted in the UK and other developing countries in improving the policies and practices in relation to organic waste management. The objectives of the project are well aligned with the UK Industrial Strategy in enhancing resource efficiency while achieving a sustainable industrial growth and a more resilient economy. The project has received support from a number of UK and international organisations (academia, industry and government), providing multidisciplinary expertise to address the global challenges in waste management.

Acknowledgement

This work was supported by the Natural Environment Research Council (NE/R012938/1) through the UKRI/NERC Industrial Innovation Fellowship Programme.

Further information

Please contact Dr Kok Siew Ng (kok.ng@eng.ox.ac.uk) if you are interested in learning more about the project.