Wet Gas Research, The Advanced Instrumentation Research Group

Wet Gas

Most two-phase applications for Coriolis mass flow metering are for low Gas Void Fraction (GVF) conditions, i.e. where the process fluid is essentially liquid with relatively low levels of entrained air or gas. There are particular challenges associated with metering wet gas, where the GVF exceeds 95%. Established wet gas metering techniques are typically based on a differential pressure-type device (for example an orifice plate or V-cone). It is well-known that such devices over-read compared to a dry gas calibration; equations to correct the reading are available if the degree of gas “wetness” is known. For Coriolis mass flow metering of wet gas, two approaches are described. The natural extension of the low GVF techniques is to map the observed mass flow and density readings onto estimates of the flow rates of the gas and liquid components. The alternative is to use the Coriolis meter to estimate the degree of gas “wetness” (e.g. the Lockhart-Martinelli number) and to apply a conventional correlation (e.g. Murdock or Chisholm) to a differential pressure flow reading. The UTC has carried out a number of wet-gas trials, including model development at the CEESI laboratory, and field trials in US and Canada.

Introduction

Natural gas produced from wells is usually not dry, but contains small quantities of liquid. Strictly speaking, “wet gas” refers to the presence of hydrocarbons heaver than ethane which, at reduced temperature and pressure conditions, tend to condense and form liquid in the upstream processing plant. The term “wet gas” is further reserved for processes where the proportion of liquid phase is no greater than about 5% by volume (or equivalently that the gas void fraction GVF is greater than 95%). However, water vapour condensing to water is often an additional liquid component of wet gas, and in mature wells ground water may find its way into the reservoir. Overall, therefore, wet gas is usually viewed as a three-phase stream consisting of gas, condensate and water. The task of a wet gas metering system is to measure the flow rates of each of these streams individually. A common simplification is to consider only two phases, gas and liquid, and to distinguish between the liquid components at a later stage in the production process.

Currently, there are three main approaches to wet gas metering. The first is to physically separate the streams before metering them individually using conventional single phase instrumentation. The second is to use a single phase meter (typically based on the differential-pressure principle, such as an orifice plate or a V-cone) on the wet gas stream, and to compensate the reading for the errors induced by the effects of wet gas. The third approach, adopted by a number of specialist suppliers, is to develop (often very expensive) truly multi-phase meters.

In the case of a flow reading based upon a differential pressure sensor across an orifice plate (DP/OP), the effect of wet gas is to cause an over-reading of the gas flow rate. The Murdock correlation is widely accepted within the industry as providing a usable correction to the DP/OP over-read:

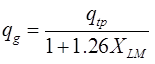

where qg is the true gas volumetric flow rate, qtp is the calculated volumetric flow rate based on the observed pressure loss across the orifice plate from the two-phase mixture, and XLM is the Lockart-Martinelli parameter, which in turn is defined as follows:

where  and

and ![]() are the mass flows of the liquid and gas respectively, and

are the mass flows of the liquid and gas respectively, and ![]() and

and ![]() are the liquid and gas densities respectively. The Lockart-Martinelli gives an indication of the wetness of the gas, ranging from a minimum of 0.0 for dry gas up to a maximum of about 0.3 for 95% GVF wet gas. Of course in general XLM is not known, and must be measured or estimated for the Murdock correction to be applied.

are the liquid and gas densities respectively. The Lockart-Martinelli gives an indication of the wetness of the gas, ranging from a minimum of 0.0 for dry gas up to a maximum of about 0.3 for 95% GVF wet gas. Of course in general XLM is not known, and must be measured or estimated for the Murdock correction to be applied.

A number of drivers are stimulating change in the use of metering in natural gas fields. The first is the rise in price of the gas and condensate products. This has several consequences, including the current substantial capital investment in new wells and metering, and the increasing scrutiny of measurement quality by stakeholders and tax revenue agencies, with particular emphasis on the proper measurement of the highly valuable condensate. A second issue is the steady growth of environmental concerns and their associated legislation. Leaks or emissions from separators are taken more seriously, and maintenance costs are rising to ensure leaks are avoided. Produced water must now be accounted for, so high quality measurement of both liquid phases is increasingly important. A final important change in the gas industry is the nature of the reservoirs now being exploited. As discussed in more detail below, ‘tight’ gas fields are increasingly being developed, where lower pressures and lower gas volumes, requiring more flexible and adaptive exploitation strategies. Good quality measurement data is required to optimise production.

Overall, therefore there are many incentives to develop a relatively low cost, low maintenance, environmentally friendly, wet gas meter providing high quality measurements. A number of new technologies are being developed to match this need.

Coriolis mass flow metering for wet gas

Coriolis flow meters have increasingly been used in multi-phase applications, but mostly in low GVF conditions. In providing two process measurements (mass flow and density) the Coriolis meter cannot provide true three-phase metering, except in conjunction with another technology (e.g. a water-cut or void fraction meter). A standalone Coriolis meter is, however, capable of acting as a two-phase meter, where the components are partitioned into a single liquid phase alongside the gas phase, and this approach is described first.

There are particular potential difficulties with using a Coriolis meter for wet gas metering. A Coriolis meter designed for liquid duty may be operating within the bottom 5% of its mass flow and density range on wet gas duty, for the same pressure drop across the flowtube. By contrast the full measurement range will be available to a volumetric instrument. This disadvantage may be compounded by the zero drift commonly observed when liquid is unevenly distributed along the wall of the flowtube, and the high noise and low flowtube amplitude commonly associated with two-phase flow. At the outset of the project, there was some concern whether the Coriolis meter would prove suitable for wet gas applications. However, the results demonstrate that excellent performance can be achieved through careful signal processing of the raw data.

Conversely, an undoubted advantage of using a Coriolis meter on wet gas duty is its ability to deal with any slugs of liquid that may be produced by the well. The rapid dynamic response of the meter ensures such (highly valuable condensate) slugs are metered accurately using conventional Coriolis two-phase metering techniques.

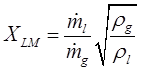

The set of calculations used in the two-phase wet gas Coriolis flow meter is involved, and requires the provision of live pressure and temperature data, so that the density of the gas phase can be computed using conventional PVT calculations. As with other forms of two-phase Coriolis metering, errors are induced into the mass flow and density readings by the non-homogenous flow, and two basic correction schemes have been considered. The first is the obvious implementation, whereby the corrected mass flow and density readings are converted into corresponding mass flowrates for the gas and liquid phases. The second scheme (Figure 1) is to generate an accurate Lockart-Martinelli parameter from the Coriolis readings, and thereby correct a conventional DP/OP meter using the Murdock equation (1).

Figure 1. Wet gas metering scheme combining Coriolis meter with DP/OP

Although the second method requires additional instrumentation, and is a less direct calculation, it has the advantage of presenting to users and regulators a more incremental advance on current practice. The scheme further provides liquid flow data not provided by a corrected DP/OP reading on its own. In addition, the redundancy between the Coriolis gas flow readings and those of the DP/OP can be used to provide consistency checking for quality assurance. Results using both schemes are reported below.

Laboratory Trials

Trials were carried out at the CEESI gas laboratory in Colorado to develop two-phase models of the meter response to wet gas. A 50mm flowtube was subject to a range of conditions, as follows:

-

Pressure range 115 – 515psi (793 – 3551 kPa)

-

Gas flow rates 0.25 – 2.5 million standard cubic feet per day (0.0397 – 0.397 Mm3 at stp)

-

Gas wetness XLM range 0 – 0.3

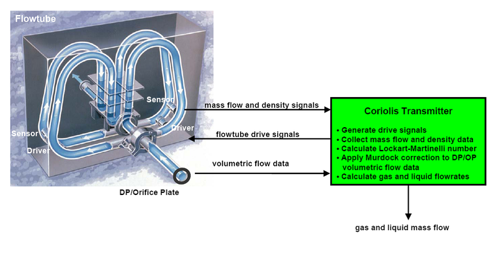

Based on the raw mass flow and density readings over the selected range of conditions, and given accurate reference measurements from the CEESI instruments, a series of models were developed of the wet gas response of the meter. These models were subsequently tested by carrying out on-line testing at intermediary points in the modelling data matrix. The results obtained at 375psi (corresponding to the operating conditions at BP’s Wamsutter field) are shown in Figures 2 and 3 below.

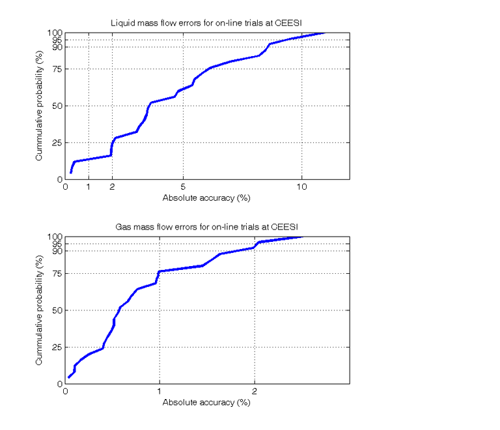

Figure 2 shows the mass flow errors for the liquid and gas readings respectively, against the gas flow rate and wetness for each trial. The same data set is represented in Figure 3, which shows what proportion of the data exhibits less than a certain level of error. For example, 95% of the tests points show a gas mass flow error of less than 2%, while 60% of the test points show a liquid mass flow error of less than 5%.

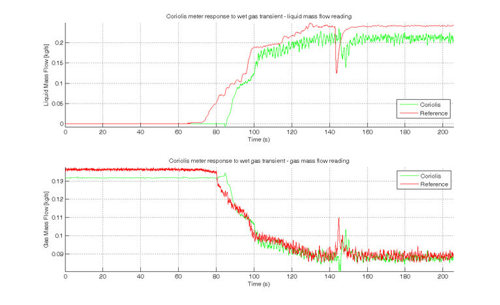

Figure 4 illustrates the dynamic response of the meter to a step change in the wet gas conditions. The liquid and gas mass flow from the Coriolis meter are shown as time series against the CEESI reference meters. Note however, that the CEESI data is indicative only, as the on-line readings are not fully calibrated. At the start of the time-series, the gas is dry; from approximately t=60s liquid is introduced into the gas stream. During the transient, there is a steady drop in the gas flow rate. It can be seen that the Coriolis meter shows a rapid and (as far as can be judged without absolute references) reasonably accurate response to the changing condition of the wet gas. Note that the delay in the meter’s response to the onset of liquid flowrate may be attributable to transport delays between the liquid injection point and the meter itself.

Overall, the CEESI trials demonstrate the viability of a Coriolis-based wet gas meter.

Figure 2. Results of on-line testing at CESSI of two-phase wet gas model on 50mm Coriolis flow meter at 375psi (2.58MPa) pressure.

Figure 3. Cumulative probability of error for results in Figure 2.

Figure 4. Times series of the Coriolis meter response to a wet gas transient during CEESI trials. The reference readings are not fully calibrated and hence indicative only.

Trial at Wamsutter Gas Field

The Wamsutter Gas Field, in Wyoming, discovered in the 1950s, is one of the largest ‘tight’ gas fields in North America, covering 4000km2. BP is the largest operator in the field, with currently some 1100 wells. In 2005 BP announced a $2.2 billion investment programme for Wamsutter, involving the drilling of 2000 new wells over a 15 year period, with the total gas recovery targeted at 450 million barrels of oil equivalent.

‘Tight’ gas is found where the permeability of the reservoir rocks is very low, so that the gas resources are difficult to extract. The gas extracted from each well is relatively low, so that more complex well geometries are often drilled with for example multiple boreholes of a single spine.

There are several challenges facing the Wamsutter development. Working within a legislative framework requiring reduced surface impact and minimal environmental impact, there is a complex field layout and ownership involving multiple operators, and only a limited infrastructure is currently in place. To realize a reduction in surface and environmental impacts, centralization of gas processing is essential. This in returns requires wet gas metering at each wellhead to provide data for production allocation. Dedicating a three-phase separator to each well is not considered economically or environmentally viable, while traditional well testing, in which a single separator measures the output of many wells, each in turn, is unlikely to yield sufficient accuracy at Wamsutter due to high flow rate variability of individual wells and periodic slugging conditions. Finally, the price of modern wet gas flow meters is prohibitively expensive for a one-per-well solution.

In the light of these issues, BP has encouraged the development of novel wet gas metering technologies, and offered a field trial facility at Wamsutter for a number of vendors. A prototype Coriolis-based wet gas meter developed by the Oxford UTC and Invensys was included in the trials (Figure 5). All the trial meters were placed in series so their results could be compared by BP. Reference measurements were provided by a conventional three-phase separator.

Figure 5. Wet gas trials at BP’s Wamsutter test site. The Coriolis-based prototype wet gas skid is in the foreground.

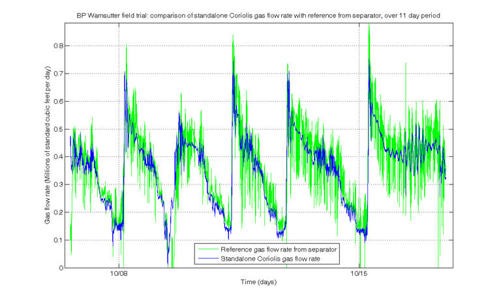

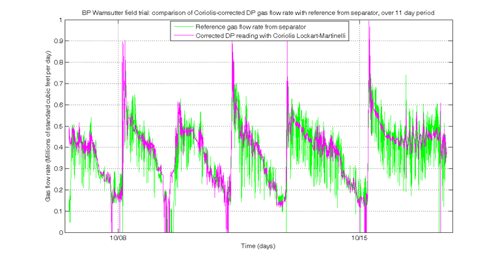

Coriolis meter results were generated for both the stand-alone and the DP/OP compensation configurations. Figures 6 and 7 show the resulting gas flowrate results, against the separator reference, for the standalone Coriolis and DP/OP correction technique, over the same 11 day trial period. The total errors over the period are -2.8% for the standalone Coriolis and -1.3% for the corrected DP/OP. Given the high levels of noise on the separator reading, especially compared with the standalone Coriolis, this difference is not seen as significant, and both systems show a good ability to track trends in the gas flow rate. Note that liquid flow data was provided by the Coriolis system, but a high quality reference from the separator was not available, and hence no comparison is provided here.

Figure 6. Comparison of standalone Coriolis gas mass flow reading against separator reference reading.

Figure 7. Comparison of separator reference reading against DP/OP reading, corrected using the Murdock correlation, where the Lockart-Martinelli number has been estimated using the Coriolis meter.