Soft Matter Photonics: Research - Laser Writing | Engineering Science Department - University of Oxford

Aberration-corrected Direct Laser Writing in Liquid Crystals & Polymers

Two-photon polymerization direct laser writing (TPP-DLW) is a technique for creating micro- and nanoscale polymer objects in polymerisable resins and is a powerful additive manufacturing/3D printing technique. The capabilities of TPP-DLW go well beyond that offered by traditional lithographic processes, as it provides true 3D structuring rather than 2D layer-by-layer fabrication. It also enables rapid prototyping and flexible, direct conversion from 3D design to 3D microstructure as well as the remarkable ability to create sub-diffraction limited polymer features. By translating a photopolymerizable liquid crystal in a controlled manner relative to the laser focus, 3D structures can be built-up from polymerized voxels (the 3D analogy of pixels) formed via free-radical polymerization. We are working closely with the Dynamic Optics and Photonics group of Professor Martin Booth and Dr Patrick Salter to develop new electro-optic effects and photonics technologies by writing micron-sized polymer features into polymerizable liquid crystal materials and devices (e.g. see Figures 1 - 3).

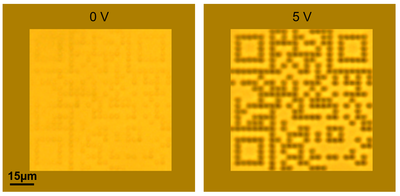

Figure 1. Read-on-Demand Microimages in Liquid Crystal Devices.

Figure 2. Laser-written polymer bicycle in a liquid crystal device.

Figure 3. Laser written QR code.

A key challenge for emerging nanoprinting techniques is to increase the functionality and capabilities of the resin materials. We are directly addressing this by developing tunable resins using stimuli-responsive liquid crystal materials that change their optical and physical properties in response to external fields. Developing such bespoke resins that incorporate polymerizable liquid crystal molecules has allowed us to lock-in different alignments of the liquid crystal director (the average pointing direction of the molecules). Thus from a single resin, we are able to engineer polymer structures with different material properties in a single-step fabrication process, leading to new electro-optic capabilities and practical applications.

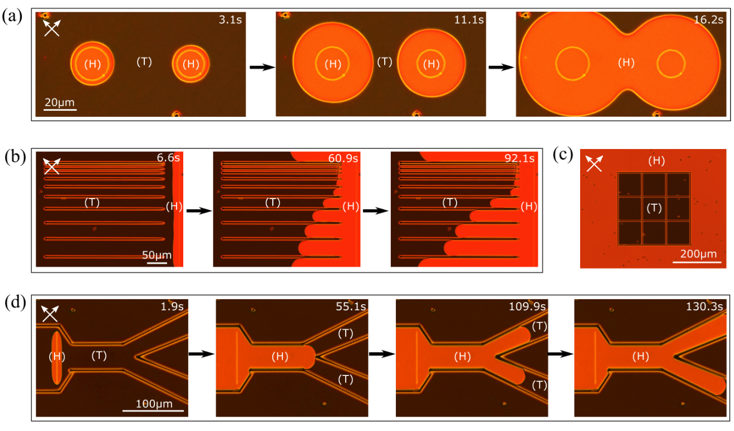

Figure 4. Controlling Defects in Liquid Crystal Devices (from Nature Communications volume 11, Article number: 2203 (2020)).

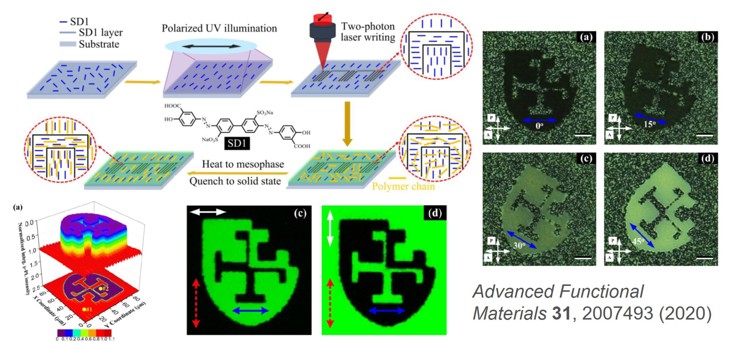

We are also using the laser fabrication technique to control the formation and propagation of defects in liquid crystal devices (see for example Figure 4) as well as the alignment of liquid crystalline conjugated polymers (Figure 5).

Figure 5. Schematic illustration of the procedure employed for the laser (re)writing of SD1 photoalignment layers to align F8BT LCCP films (from Advanced Functional Materials 31, 2007493 (2020))

Research Team

Bohan Chen, Camron Nourshargh, and Zimo Zhao

Publications

Multielement Polychromatic 2D Liquid Crystal Dammann Gratings

Zimo Zhao, Bohan Chen, Patrick S. Salter, Martin J. Booth, Dominic O'Brien, Steve J. Elston, Stephen M. Morris Advanced Materials Technologies (2022)

Laser Written Stretchable Diffractive Optic Elements in Liquid Crystal Gels

Bohan Chen, Zimo Zhao, Camron Nourshargh, Chao He, Patrick S. Salter, Martin J. Booth, Steve J. Elston and Stephen M. Morris Crystals 12(10), 1340 (2022)

3D Switchable Diffractive Optical Elements Fabricated with Two-Photon Polymerization

John Sandford O'Neill, Patrick Salter, Zimo Zhao, Bohan Chen, Hassan Daginawalla, Martin J. Booth, Steve J. Elston, Stephen M. Morris Advanced Optical Materials 10, 2102446 (2022)

Yuping Shi, Patrick S. Salter, Mo Li, Robert A. Taylor, Steve J. Elston, Stephen M. Morris, Donal D. C. Bradley Advanced Functional Materials 31, 2007493 (2020)

Electrically-tunable positioning of topological defects in liquid crystals

John J. Sandford O’Neill, Patrick S. Salter, Martin J. Booth, Steve J. Elston, Stephen M. Morris Nature Communications 11, 2203 (2020)

Read on Demand Images in Laser‐Written Polymerizable Liquid Crystal Devices

Chloe C. Tartan, John J. Sandford O'Neill, Patrick S. Salter, Jure Aplinc, Martin J. Booth, Miha Ravnik, Stephen M. Morris, Steve J. Elston Advanced Optical Materials 6, 1800515 (2018)

C. C. Tartan, P. S. Salter, T. D. Wilkinson, M. J. Booth, S. M. Morris, and S. J. Elston RSC Advances 7, 507-511 (2017)

Localised polymer networks in chiral nematic liquid crystals for high speed photonic switching

Chloe C. Tartan, Patrick. S Salter, Martin J. Booth, Stephen M. Morris & Steve J. Elston Journal of Applied Physics 119, 183106 (2016)