Soft Matter Photonics: Research - Precision Printing | Engineering Science Department - University of Oxford

Precision Printing of Liquid Crystals & Polymers

Our research, which is in collaboration with the Fluid Dynamics group led by Professor Alfonso Castrejon-Pita, involves the printing of liquid crystals (LC) and polymer composites for the fabrication of next-generation thin-film optical elements and devices. Drop-on-Demand (DoD) inkjet printing is a non-contact technique that allows for the precise deposition of pico-litre volume droplets of ink to create micron-sized objects. The capabilities of DoD printing go well beyond the contact-based printing methods, such as gravure offset and screen printing, as it provides greater flexibility in terms of the variety of materials that can be deposited using a layer-by-layer approach on a range of substrates and surfaces including flexible substrates.

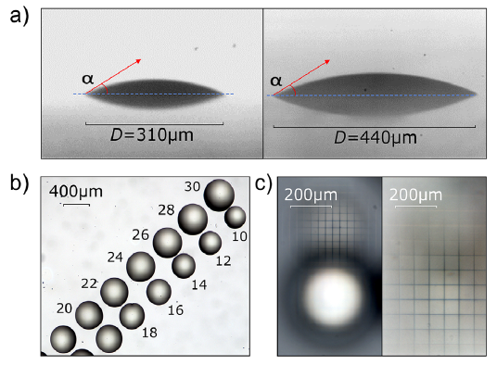

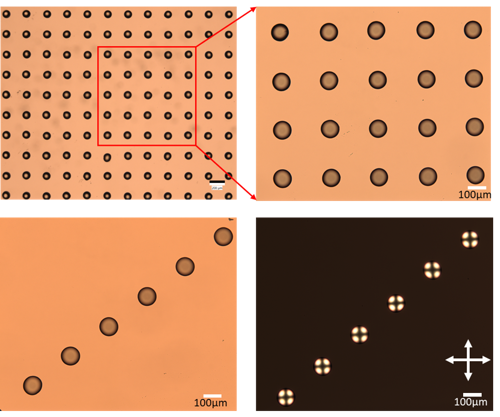

Figure 1. An array of printed nematic LC microlenses.

Figure 2. Printed nematic LC arrays.

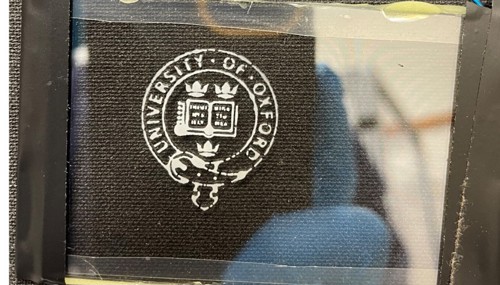

LCs are a class of functional fluid that possess unique electro-optical properties, providing enormous opportunities for the development of active and passive optical components. Combining LCs and DoD inkjet printing opens up new pathways in the fabrication of functional thin-film optical elements and devices (such as tunable Microlens arrays as shown in Figures 1 and 2). Following suitable preparation of the printing substrate, as well as the precise deposition of the LC based inks, it is possible to engineer structures and configurations that exhibit special optical properties (Figure 3).

Our work includes a broad and in-depth investigation of the printing conditions that are required to deposit a range of LC ink formulations in a controlled and precise manner without the formation of satellite droplets or jet break-up. We are also study the effect of substrates on the printed drop formation as well as possible thin-film optical elements that can be fabricated using this additive manufacturing technique. We use a combination of high-speed imaging involving both shadowgraphy and polarising optical microscopy systems, which enables both the deposition of the droplets and the alignment of the LCs to be tracked in real time.

Figure 3. Printed logo using polymer dispersed liquid crystal (PDLC) ink formulations.

Publications

Printed Polymer-Stabilized Chiral Nematic Liquid Crystal Privacy Windows

Mengmeng Li, Waqas Kamal, A.C.J. Orr, Alfonso A. Castrejón-Pita, Steve J. Elston, Stephen M. Morris Macromolecular Chemistry and Physics (2022)

Spatially Patterned Polymer Dispersed Liquid Crystals for Image-Integrated Smart Windows

Waqas Kamal, Mengmeng Li, Jia-De Lin, Ellis Parry, Yihan Jin, Steve J. Elston, Alfonso A. Castrejón-Pita, Stephen M. Morris Advanced Optical Materials 2101748 (2021)

Electrically Tunable Printed Bifocal Liquid Crystal Microlens Arrays

Waqas Kamal, Jia‐De Lin, Steve J. Elston, Taimoor Ali, Alfonso A. Castrejón‐Pita, and Stephen M. Morris Advanced Materials Interfaces 7, 2000578 (2020)

Ellis Parry, Dongjin Kim, Alfonso Castrejon-Pita, Steve J. Elston, and Stephen M. Morris Optical Materials 80, 71–76 (2018)

Drop-on-Demand Inkjet Printing of Thermally Tunable Liquid Crystal Microlenses

E. Parry, S. Bolis, S. J. Elston, A. Castrejon-Pita and S. M. Morris, Advanced Engineering Materials 20, 1700774 (2017)