Research in the Thermal Propulsion Systems Group, Department of Engineering Science University of Oxford - Thermal Propulsion Systems; Fast coriolis meters for real-time on-engine measurement of fuel injector flow

Fast coriolis meters for real-time on-engine measurement of fuel injector flow

Accurately measuring how much fuel is being used in fuel injectors is essential for monitoring both gasoline and diesel engine performance. Current technology allows us to do this for the whole engine over many injections, but not for each injection event. This project has taken technology already used widely in the oil and gas industry (the Coriolis mass flow rate meter) and has adapted it to provide high-speed flow rate information for an individual Diesel injector. We call this Fast Next Generation Coriolis (Fast NGC). Oxford's patented signal processing and filtering methods provide the Fast NGC with the potential to both measure the fuel mass injected in a single injection and to display this information in real time. The filtering tools will also enable on-engine operation of the Fast NGC. The ability to measure changes in injector flow rate on-engine, for example due to injector ageing, would enable engine control systems to compensate in-service, improving combustion control and reducing emissions.

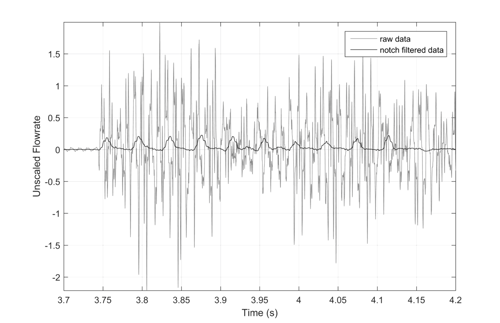

We have recently completed a feasibility study on the Fast NGC concept with funding from the 'Preparing for the Grand Challenges' program of Advanced Propulsion Centre UK. Figure 1 below shows the efficacy of the Oxford 'Prism' filtering methodology and the ability of Fast-NGC system to capture individual diesel injection events. The time response of the Fast-NGC system, currently demonstrated with a production flow tube, is world leading.

Figure 1: Raw and 'Prism' filtered signals, 10 injection burst

Having established the feasibility of our methods, we are now working with our partners and sponsors on a proposal to develop the new hardware and filtering techniques required to precisely measure the fuel mass flow in each event, with the ultimate target of resolving injection rate shape at diesel injection pressures.

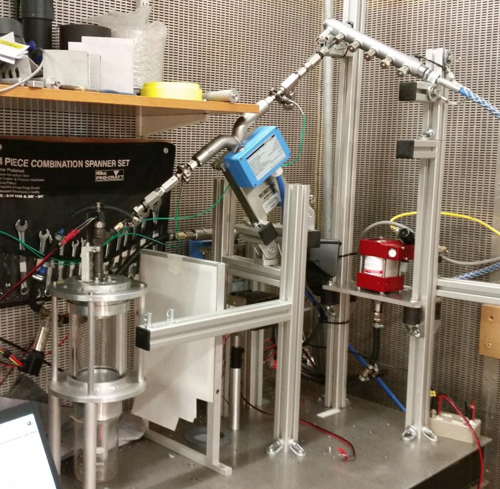

Figure 2: Diesel spray rig configured for Fast-NGC testing

A paper at SAE WCX2018 described our application of the Fast-NGC instrumentation to a diesel injection rig. The paper identifies some of the technical challenges associated with our proposed measurement method, discusses technical solutions and demonstrates the potential for high repeatability. The full paper citation is:

Leach, F., Davy, M., Henry, M., Tombs, M. et al., "A New Method for Measuring Fuel Flow in an Individual Injection in Real Time," SAE Technical Paper 2018-01-0285, 2018, available here.

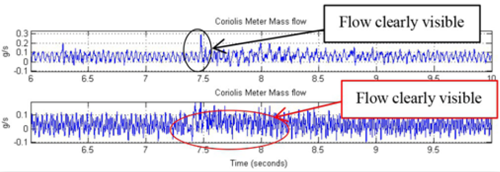

Figure 3 (below) shows one of the key results from the work, by applying Fast-NGC devices to both the feed and return lines together with high-speed imaging we were able demonstrate that very short injector energising times -- such as might be used in future digital rate shaping applications -- can lead to fuel effectively bypassing the injector nozzle, i.e. there is fuel flow but no injected fuel mass.

Figure 3: Flow measured when no fuel injected: Coriolis feed (upper) and return (lower) line data for the 1000 bar, 0.1 ms ET case. Flow can clearly be seen in both lines.

Currently, we are studying the potential of Fast-NGC meters applied Gasoline Direct Injection (GDI) engines. Significant progress has been made to date. The work has attracted the support of BP through the allocation of an EPSRC iCASE award to Maruthi Malladi and preliminary studies have been completed. The findings from this first GDI study have now been written up and will be presented at the SAE International Powertrains, Fuels & Lubricants Meeting in San Antonio, TX, USA, January 22-24, 2019. Sample results will appear here once they are cleared to enter the public domain.

Leach FCP, Davy MH, Henry MP, Malladi MR, Tombs M, Zhou F, Gold M, Pearson R, “Fast NGC: A new on-line on-engine measurement technique for fuel flow measurement”. SAE Technical Paper 2019-01-0062, doi:10.4271/2019-01-0062

Principal Investigator:

Co-Investigators:

Professor Manus Henry, Professor Martin Davy

Post-Doctoral Researchers:

Dr Michael Tombs, Dr Feibiao Zhao, Dr Joseph Camm,

Graduate Research Students:

XiaoHang (Leo) Fang, Maruthi Malladi

Funding and Support