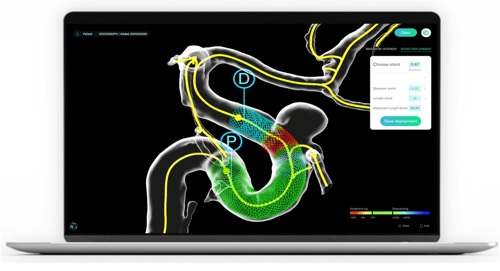

Alumna Dr Katerina Spranger is bringing vital engineering innovation to hospitals. Dr Spranger’s software platform, PreSize, is powered by AI to accurately simulate how medical devices would behave once implanted into a patient. For stents, used to treat brain aneurysms, such simulations could help the surgeons choose the right size of stent before they start surgery.

Dr Katerina Spranger completed her DPhil in Biomedical Engineering at Oxford in 2014, focusing on modelling medical device implantation under the supervision of Professor Yiannis Ventikos. Fast forward 10 years, and as founder and CEO of Oxford Heartbeat she is bringing vital engineering innovation to hospitals in a first-of-its-kind UK-wide clinical trial of software as a medical device in neurology space, supported by the National Institute of Health and Care Research (NIHR) – software that is CE-mark approved and already being used in 10 hospitals across the country.

A lot of planning and meticulous research went into the design of Dr Spranger’s software platform, PreSize, which is powered by AI to accurately simulate how medical devices would behave once implanted into a patient. For stents, used to treat brain aneurysms, such simulations could help the surgeons choose the right size of stent before they start surgery - too small, and it could end up travelling dangerously around the body; too big, and it could block blood flow from going to important brain arteries that relate to, for example, vision. Traditionally this choice has been done by eye.

“The software is designed to be super simple, requiring minimal training, and allowing surgeons to prep for a surgical case in a matter of minutes."

The platform Katerina wanted to build would improve their ability to choose the correct stent for each patient, reducing surgery times, improving patient outcomes, and saving costs. “We spoke to as many surgeons as possible, finding out what they would want and what functionality they needed in the software that could help show how a medical device will behave after implantation, to take away the guesswork element”, she says.

“Everything is so tiny in the brain, there is a huge need to provide greater accuracy for this type of surgery”, she adds. “The software is designed to be super simple, requiring minimal training, and allowing surgeons to prep for a surgical case in a matter of minutes. I knew it had to work in high-risk, high-pressure conditions, in the operating theatre with a lot of people involved and a lot at stake. Time in those circumstances is of the essence”.

"I knew that I needed to speak to potential users as early as possible, to always keep in mind who you are designing the solution for"

Developing a programme like this, which is classified as a medical device, and getting it approved for use, meant a great deal of groundwork. “During my DPhil at Oxford I did an extra course around Science Innovation at the Said Business School, which was aimed at science students interested in business. From what I learned from the course I knew that I needed to speak to potential users as early as possible, to always keep in mind who you are designing the solution for, if you want it to be successfully adopted”.

After her DPhil Katerina won an RAEng Enterprise Fellowship, which provides early-career researchers with training, support, mentoring, and funding to set up companies. She was able to hire two part-time students to assist with the investigation stage. Katerina herself observed stent procedures at an Oxford hospital, helping her to visualise exactly how her device would be used in practice. “I was then lucky enough to obtain Government funding through Innovate UK to build the technology with a professional team, working with software developers and translate my idea into an actual product. Because it is classified as a medical device, everything had to be of the highest quality and thoroughly tested.”

"The training I was able to access while I was studying at Oxford taught me about the Lean Startup methodology, and was a fantastic preparation for starting my company”

Katerina was encouraged in her education and career ambitions by her parents, both engineers themselves, who never considered that gender should be a barrier to a successful career in science. “I’ve always been fascinated by how powerful technology can be in providing fantastic engineering solutions. But so many wonderful ideas, beautifully executed from an engineering point of view by talented engineers, don’t translate into the real world. The year we spent doing groundwork before developing PreSize easily saved us 3 or 4 years down the line in producing something that users actually wanted. The training I was able to access while I was studying at Oxford taught me about the Lean Startup methodology, and was a fantastic preparation for starting my company Oxford Heartbeat.”

Although the device is CE-Marked in Europe, and already in use successfully in many hospitals, Katerina wanted to capture its impact objectively and quantitatively through an independent clinical trial, currently taking place on a range of patient demographics and types of procedures across the UK. The trial will compare how long procedures take using PreSize compared to surgeries where it is not used, whether there were any complications, whether it is more efficient in the planning and execution, reduces waste of devices that are implanted unsuccessfully, and how much it helps to reduce the surgical team’s exposure to radiation. “We are already seeing fantastic results, showing an accuracy rate of 95%, which confirms the qualitative feedback we have had from users – that it is easy to use, user-friendly and exactly what they needed”.

“I am passionate about creating beautifully designed products, that are powerful, simple and effective”.

Katerina is clearly passionate about her subject and the benefits engineering innovation can bring in the real world. She is equally proud of the fact that a device donated to hospitals in her home country, the Ukraine, has been successfully used on patients and the results documented in a Ukraine medical journal. She found reading that paper very moving, she says. Looking forward to the future, the entrepreneur has lots of other ideas, all connected to improving the preparation for and execution of minimally invasive surgeries. “I am passionate about creating beautifully designed products, that are powerful, simple and effective”.

Safe Inspection of Tall Buildings

Oxford Robotics Institute