A substantial amount of new infrastructure is required to cope with growing populations and the effects of climate change ‒ and efficient use of underground space appears the most viable and sustainable solution. The ‘FOCUS’ project is innovating in the underground construction sector to provide more cost-effective and sustainable critical infrastructure.

Digital Underground Construction: Efficient Delivery of Sustainable Infrastructure

Growing populations and the effects of climate change have placed unprecedented pressures on utility (e.g. water and wastewater) and transport systems worldwide. A substantial amount of new infrastructure is required in the UK alone ‒ and efficient use of underground space appears the most viable, if not the only, sustainable solution. Whilst construction is beginning to enjoy exciting innovations, these relate primarily to above-ground activities. Similar advances underground have been obstructed by key residual uncertainties relating to structural interaction with soil. This is particularly the case for (micro-) tunnelling, shafts and deep excavations where ‘soil-structure interaction (SSI)’ plays a crucial role in the construction process.

Supported by the Royal Academy of Engineering and the Engineering and Physical Sciences Research Council, the 'FOCUS' project is delivering step-change innovations for the underground construction sector to provide more cost-effective and sustainable critical infrastructure. The project centres on the use of live construction data to inform and optimise site operations, and the analysis of monitored data to deliver the underpinning engineering science for more cost-effective and sustainable design. This involves novel sensing technologies, machine learning, advanced numerical analysis (“underground digital twins”) and reduced-scale laboratory modelling.

Dr Brian Sheil, Royal Academy of Engineering Research Fellow and project PI says, “The construction sector is a cornerstone of the UK economy – it has a vital role to play in our post-covid economic recovery. However, inefficiencies are present in almost all areas of the construction ecosystem. These inefficiencies increase the cost to the taxpayer but also lead to significant environmental impacts due to material wastage and increased pollution.”

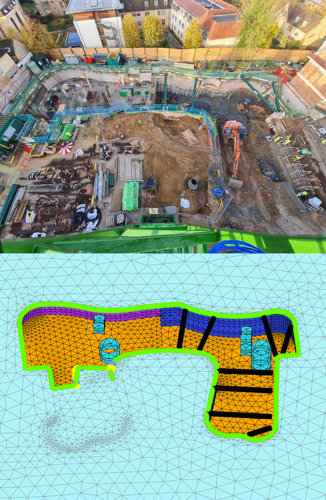

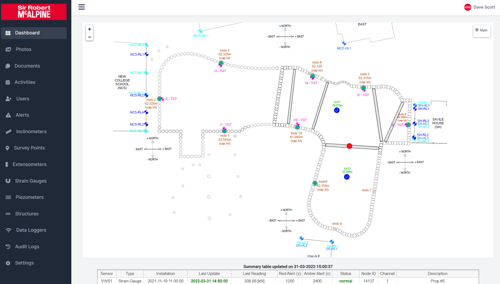

Recent output from Dr Sheil’s research team in the Department of Engineering Science has included the development of novel instrumentation and monitoring systems to optimise the delivery of deep excavations. Recent projects include the basement excavation Oxford Gradel Quads at New College Oxford, with industry partners Sir Robert McAlpine, and an incinerator bunker excavation for the PROTOS energy-from-waste facility in Chester, alongside Ward and Burke Construction Ltd.

The Oxford team, which includes postdoctoral researcher Dr Zhandos Orazalin (Postdoctoral researcher) and MSc student Peter Hensman (MSc student) developed new sensors to measure soil pressures acting on the supporting walls of the excavation which are a critical aspect of design and safety. The sensors work by combining state-of-the-art fibre optic sensing with machine learning to convert discrete surfaces of these structures into smart ‘touch pads’.

Dr Sheil explains, “At Oxford, we are tackling construction pain points through a combination of new sensing systems, artificial intelligence and digital twins to help designers and site engineers optimise underground construction operations. We have recently collaborated with Ward and Burke Construction Ltd and Sir Robert McAlpine on two separate deep excavation projects to deploy real-time monitoring systems with consolidated web-based feedback of all live construction data to inform construction.”

Most sites are equipped with traditional geotechnical instrumentation, but the collected data is usually delivered in a piecemeal fashion and is not readily available in a practical way. It is difficult to interpret the overall performance of the system and compare the measurements with the initial design assumptions. Innovative techniques used in these projects to address these challenges include a combination of diverse geotechnical instrumentation, ‘on-the-fly’ 3D finite element analysis and a comprehensive online system for data access through mobile devices.

New technology enables automated data collection, online visualisation, and the maintenance of large digital databases. For these projects, the Oxford team deployed a real-time data monitoring and web-based visualisation system that included the capabilities to consolidate all types of instrumentation data into a common environment and serve as a central storage of essential project records. It allowed the processing and presenting of monitoring data in a user-friendly graphical format to compare and contrast the various instrumentation data and given baselines such as sensor location, alert values, initial design, and trigger levels. Innovative technologies allow the comprehensive understanding of construction performance which is the source of potential savings in cost and time for the existing and future projects.

Dr Sheil says, “Inefficiencies in construction can partly be attributed to a lack of innovation as the sector has been traditionally more conservative compared to other industries due to the high cost of mistakes. However, we are now starting to enjoy a technological revolution in the construction industry and we are seeing early adopters of new science and technology experience substantial benefits from design through to implementation.”

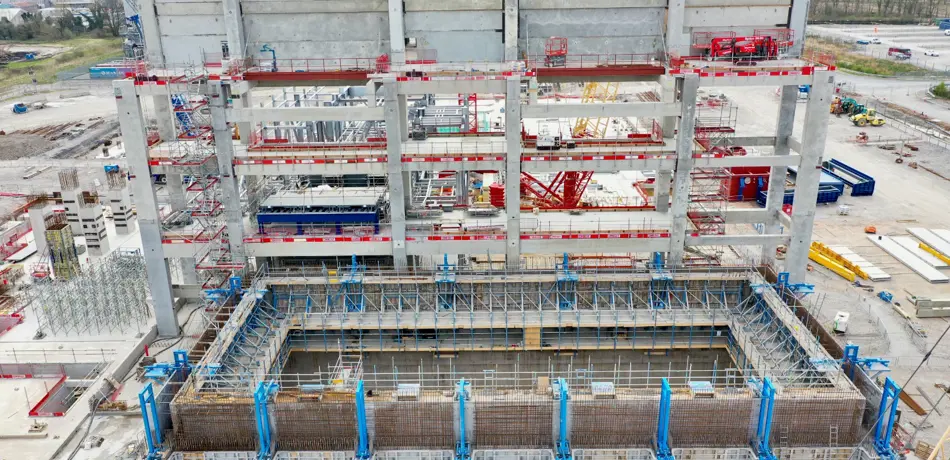

Incinerator bunker excavation for the PROTOS energy-from-waste facility in Chester, alongside Ward and Burke Construction Ltd.

Opportunities in Leicestershire’s nutrient streams

Sustainable waste management