20 Jan 2025

A green fuels breakthrough: bio-engineering bacteria to become ‘hydrogen nanoreactors’

Researchers at the University of Oxford’s Department of Engineering Science have made major advances towards realising green hydrogen – the production of hydrogen by splitting water, powered by renewable energy

L to R: Professor Wei Huang with DPhil students Haris Saeed, Michael Lewis and Weiming Tu

The researchers' approach, which focuses on bio-engineering bacteria to become ‘hydrogen nanoreactors’, could open the way towards a cost-effective, zero carbon method of generating hydrogen fuels.

Hydrogen could play a key role in helping us achieve net-zero emissions, since this burns cleanly without releasing CO2. However, current industrial hydrogen production depends heavily on fossil fuels, generating approximately 11.5–13.6 kilograms of CO2 emissions per kilogram of hydrogen produced.

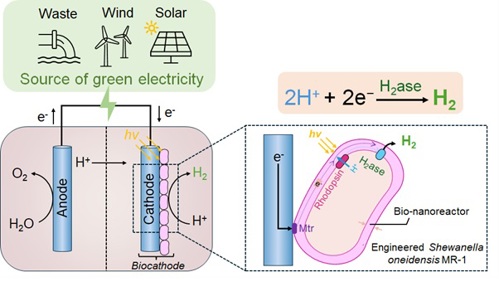

In the new study, the researchers used a synthetic biology approach to convert a species of bacteria into a cellular ‘bionanoreactor’ to split water and produce hydrogen using sunlight. By generating a highly-efficient, stable and cost-effective catalyst, this overcomes one of the critical challenges that has been holding back green hydrogen to date.

Professor Wei Huang and his group explain the concept of producing hydrogen using bacterial nanoreactors.

Lead author Professor Wei Huang explains, "Currently, most commercially used catalysts for green hydrogen production rely on expensive metals. Our new study has provided a compelling alternative in the form of a robust and efficient biocatalyst. This has the advantages of greater safety, renewability, and lower production costs, all of which can improve long-term economic viability."

In nature, specific microorganisms can reduce protons (H+) to hydrogen (H2) using hydrogenase enzymes, however this is limited to low yields due to constraints, such as low electron transfer rate. Up to now, this has prevented microorganisms from being used as effective hydrogen catalysts.

To overcome this, the Oxford researchers engineered the bacterium Shewanella oneidensis to concentrate electrons, protons, and hydrogenase in the space between the inner and outer membrane (known as the periplasmic space, 20-30 nm wide). This species is ‘electroactive’, meaning that it can transfer electrons to or from solid surfaces outside their cells.

To enhance electron and proton transfer, the team engineered a light activated electron pump (called Gloeobacter rhodopsin) onto the inner membrane, newly enabling it to efficiently pump protons into the periplasm in the presence of light. The Gloeobacter rhodopsin itself was engineered by the introduction of the pigment canthaxanthin (which absorbs light energy) to boost proton pumping by harvesting extra photon energy from sunlight. Additionally, nanoparticles of reduced graphene oxide and ferric sulfate were introduced to enhance the electron transfer. Finally, the hydrogenase enzyme in the periplasmic space was also overexpressed.

When the engineered S. oneidensis strain was exposed to electrons from an electrode, this achieved a ten-fold increase in hydrogen yield compared to a control, non-engineered strain.

According to the researchers, the system could be scaled up to produce ‘artificial leaves’, with the engineered cells printed onto carbon fibre cloth. When these artificial leaves are exposed to sunlight, they would immediately begin producing hydrogen.

First author of the study Weiming Tu, a DPhil candidate in Oxford’s Department of Engineering Science, says, "The natural periplasm of S. oneidensis offers an optimal nano-environment for hydrogen production, as it effectively ‘squeezes’ protons and electrons, thereby increasing the likelihood of their interactions within nanoscale spaces. Thermodynamically, this design results in a lower energy requirement for hydrogen production. This work is a good demonstration of engineering biology."

Co-author Professor Ian Thompson adds: ‘Efficient, affordable, and safe green hydrogen production is a long-standing goal. Our bionanoreactor has suggested the potential of biocatalysts for clean energy production. The abiotic materials used in this work, including the graphene oxide and ferric sulfate nanoparticles, were synthesised by biological methods, making them more eco-friendly than traditional chemical approaches."

This work was published as the paper 'Engineering bionanoreactor in bacteria for efficient hydrogen production' in Proceedings of the National Academy of Science.

This advance builds on the expertise Professor Huang’s lab group have developed in sustainable synthetic biology. In 2023, his group achieved a world-first in successfully bio-engineering a non-photosynthetic bacterium (called Ralstonia eutropha) to become photosynthetic – a pivotal proof-of-concept for the field. Similar to the Shewanella hydrogen nanoreactors, this system used rhodopsin, but this time as a replacement for the pigment chlorophyll (which normally powers photosynthesis). Nature Communications article.

Their achievement led to follow-on funding from UK Research and Innovation (UKRI) and the Science and Technology Agency (JST) in Japan to further develop new artificial photosynthetic cell systems to enhance green biotechnology. Alongside Professor Hiroyuki Noji (The University of Tokyo), Professor Wei Huang is leading a collaboration of eight UK and Japanese Universities to research new sustainable methods to convert carbon dioxide into useful bioproducts (such as biodegradable plastic). Ultimately, this could provide sustainable sources of important products for a diverse range of industries including healthcare, biomanufacturing, and agriculture.