29 Aug 2025

Oxford part of consortium aiming to revolutionise how aerospace technologies are manufactured

A consortium led by Honeywell (NASDAQ: HON) has received UK Government funding for a project that aims to revolutionize how critical aerospace technologies are manufactured in the UK through the use of AI and additive manufacturing

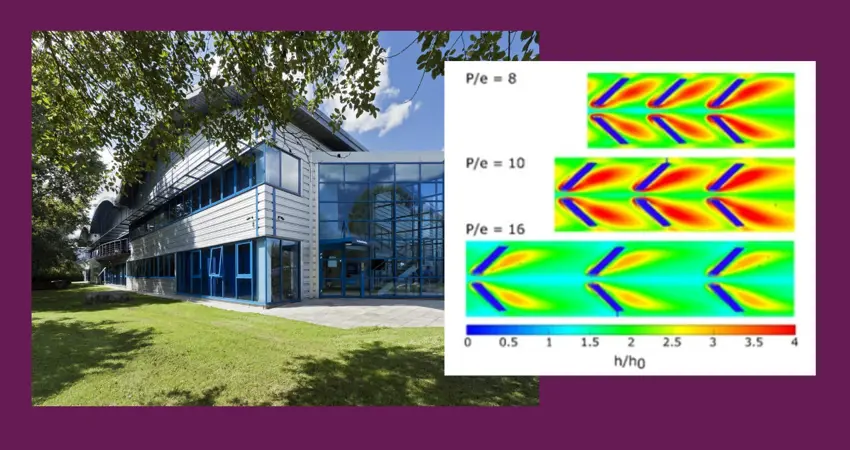

Inset: Contours showing heat transfer coefficient enhancement levels - earlier work at the Oxford Thermofluids Institute, pictured left

The £14.1m research and development project, funded through the ATI Programme, will explore how AI and other technologies can drive simulations and modelling that could lead to accelerated innovation cycles. It will also explore opportunities to increase efficiency, reduce Scope 3 emissions and help address supply chain challenges through the production of additively manufactured qualified aerospace parts.

Project STRATA will focus on the development of five innovative components within Environmental Control Systems (ECS) and Cabin Pressure Control Systems (CPCS) aboard aircraft. These complex technologies manage the cabin environment and ensure flyer safety and comfort.

The project represents a major shift in aerospace component design and manufacturing to provide benefits for manufacturers, operators and their passengers

STRATA will also advance thermal management technology for next-generation aircraft that is aimed at reducing the amount of energy required for heating and cooling of aircraft, as well as fuel consumption in-line with STRATA’s goal of supporting net-zero aerospace manufacturing and broader environmental objectives.

The project represents a major shift in aerospace component design and manufacturing to provide benefits for manufacturers, operators and their passengers including improved aircraft efficiency, faster additive manufacturing and supply chain development, and AI-driven modelling and simulation

“Additive manufacturing has the ability to deliver both high-performance optimised components and the consolidation of complex assemblies into a single part, which can lower manufacturing costs, reduce waste and deliver new efficiencies in manufacturing,” said Jacqueline Castle, Chief Technology Officer of the Aerospace Technology Institute.

The Oxford Thermofluids Institute (OTI) at the Department of Engineering Science will partner Honeywell alongside Qdot, an Oxford University spin out, to research heat transfer enhancement technologies for use in aerospace compact heat exchangers which are manufactured using Additive Manufacture (AM).

These technologies will include heat exchanger geometries such as carefully designed surface treatments included at the design stage. Opportunities arise from the use of AM due to its ability to produce bespoke features which cannot be produced by conventional machining methods.

Professor Peter Ireland FREng, OTI Director, says, “This research will build an understanding and quantification of the impact of AM on heat transfer enhancement device performance, with the outcome that the partners will be able to design heat exchangers with optimum performance.”

“STRATA represents a commitment to take the UK’s aerospace manufacturing leadership to new levels through the use of cutting-edge technology," said Anthony Florian, President, Honeywell Aerospace Technologies EMEAI. "This is an exciting opportunity to bring our deep experience in driving cross-sector aerospace research and local engineering capabilities to accelerate the development of more efficient aircraft components in the UK.”