For centuries, engineers have sought to prevent structures from buckling under heavy loads or large impacts, constructing ever larger buildings and safer vehicles. However, recent advances in soft matter are redefining the way we manipulate materials.

An age-old aversion to buckling is being recast in a new light as researchers find that structural instabilities can be harnessed for functionality. This paradigm shift, from buckliphobia to buckliphilia, permits re-evaluation of the potential of soft, deformable structures, opening up methods of exploiting buckling to tune material characteristics or develop metamaterials.

Elastic instabilities provide a means of generating regular topographies with a well-defined wavelength. For example, a thin elastic film attached to a softer substrate buckles into an array of regular wrinkles under quasi-static compression. The wrinkle wavelength is selected by the mechanical properties of the system, so that different wavelengths are typically attained through variation of the film thickness. In an article recently published in the Proceedings of the National Academy of Sciences (PNAS) Oxford Mathematicians Finn Box, Doireann O’Kiely, Ousmane Kodio, Maxime Inizan, and Dominic Vella and Alfonso A. Castrejón-Pita from our Fluid Dynamics Laboratory show that, for a film of given thickness, variation in the wrinkle wavelength can instead be achieved via impact.

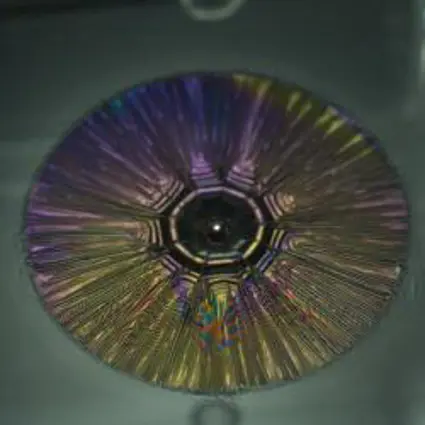

The researchers dropped steel spheres onto ultra-thin sheets of polystyrene, floating on water, and filmed what happened with a high-speed video camera. They found that ballistic impact caused the floating sheet to retract inwards, and the compression associated with this retraction induced buckling – resulting in a striking pattern of radial wrinkles.

Importantly, the distance between neighbouring wrinkles was found to evolve in time (equivalently, the number of wrinkles decreased in time) in stark contrast to previous observations in both static indentation experiments and previous dynamic impact experiments. Through mathematical modelling and systematic experimentation, the researchers found that the inertial response of the liquid substrate (i.e. the water on which the sheet floats) controlled the evolution of the wrinkle pattern.

This demonstration of wrinkle coarsening suggests that a dynamic substrate stiffness may provide a means of breaking away from the single, static wavelength that is selected by material properties alone, opening the route towards dynamic tuning of wrinkle-patterned topographies. This novel method for tunable wrinkle formation may prove to be a useful fabrication technique in a range of engineering applications that require regular, patterned topographies.

In their work, the researchers demonstrated that rapid coarsening of wrinkle wavelengths occurs with wavelengths on the order of 100 microns, making it readily observable. The uncovered mechanism for wrinkle formation is scale-independent, however, which indicates that this dynamic method of altering surface structure is suitable for reproduction at the nanoscale where the lengthscale of the wrinkles would be small enough for use in optical applications including photonic materials, which require periodic structures with period comparable with the wavelength of visible light. The reported dynamic wrinkling of thin, floating sheets is fast though, occurring within 10s of milliseconds – blink twice and you’ll miss it.

Bringing reliable power to Sierra Leone

Electrical Engineering