Bamboo is a highly versatile plant with a wide range of uses that has been hailed a ‘wonder’ plant due to its exceptionally fast growth, low cost, and low environmental impact. New research undertaken at the Multi-Beam Laboratory for Engineering Microscopy (MBLEM) at Oxford’s Department of Engineering Science explores its capabilities deeper and further.

What does the new research tell us?

The team at MBLEM looked into how chemical treatments can change the physical properties of bamboo. They applied different concentrations of Sodium Hydroxide (NaOH) to a bamboo variety called ‘Golden Goddess’ and put it under tests of tensile strength - the maximum stress a material can undergo through stretching or tearing - to determine the specific ways in which it is deformed while applying different levels of force.

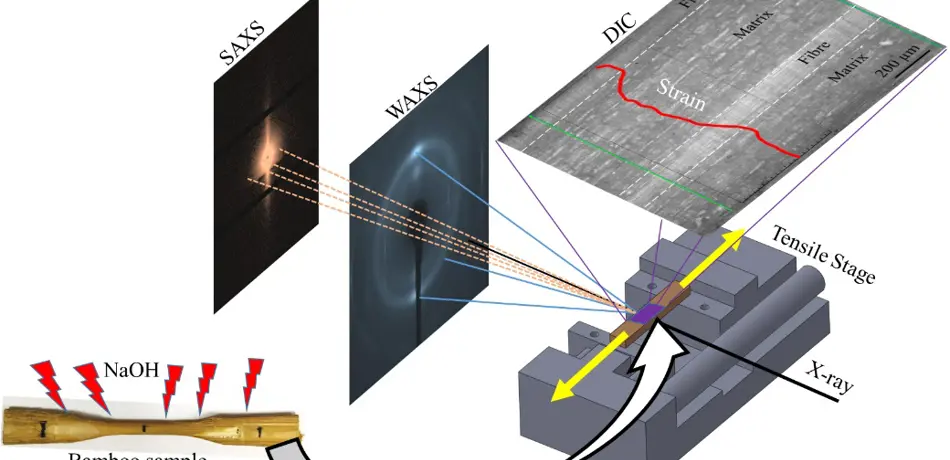

A diagram showing the set up of the experiment.

After treating the bamboo with a solution of 20% NaOH and water for just 20 minutes, the material became stiffer by 59% compared to untreated bamboo. However, treating the same bamboo material with a solution of greater than 20% NaOH concentration made the bamboo more flexible by up to 37%. Both of these results signal a change in the property called the ‘elastic modulus’. The elastic modulus measures how resistant a substance is to being deformed elastically, i.e. reversibly. An example of this is how a spring can be pulled and squashed but return to its original shape, a spring with a high elastic modulus would be more difficult to pull or squash.

The researchers were also able to image and analyse the detailed mechanisms of how bamboo deforms while it was being tested, using synchrotron X-ray scattering and Digital Image Correlation. Synchrotron machines accelerate electrons to high speeds very close to the speed of light so that they emit X-ray light particles (photons). By directing these X-ray photons at a material and measuring the way they scatter it is possible to figure out the internal structure. Digital Image Correlation, on the other hand, is an observation technique that tracks changes in the outer shape and dimension. Using the combination of these techniques the researchers found that higher concentrations of NaOH are likely to disrupt the bonding between bamboo fibres which in turn reduces the strength, stiffness and toughness of bamboo.

Lead author Dr Enrico Salvati.

Postdoctoral researcher and lead author Dr Enrico Salvati (now Assistant Professor at the University of Udine) explains: “Our analysis using the combination of in situ synchrotron scattering techniques and an optical method allowed detailed evaluation of the modification of mechanical properties induced by NaOH treatments."

"Given the wide range of applications to complex natural and engineered materials, these results are certain to motivate further investigations.”

Head of the MBLEM team, Professor Alexander M. Korsunsky adds: “This study illustrates how multiscale methods of deformation analysis developed at MBLEM help shed light on the properties of bamboo, a fascinating example of Nature’s hierarchically structured materials.”

Being able to manipulate and enhance the properties of bamboo provides a basis for further research into developing even more uses for this fascinating material.

Why is bamboo so exciting?

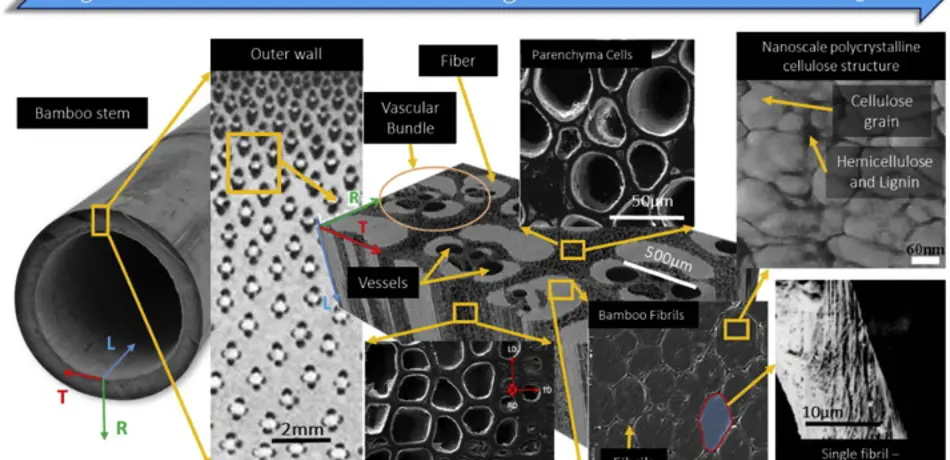

Bamboo is strong and light. When compressed, it is stronger than wood, brick and concrete. If you pulled or stretched it it’s stronger than steel. It is also incredibly versatile with a vast range of applications, from kitchen utensils to scaffolds for building construction. The reason it has these properties is down to the structure that spans from scales as small as a millionth of a metre (‘nanostructuration’) up to those visible with the naked eye. Bamboo has a hierarchical structure and an intricate variation of properties. For example, fibres within the bamboo stem are concentrated within the outer wall, making the plant stiffer and stronger overall. Each fibre itself is made of a number of “fibrils”, and the fibres are twisted like threads to make strong ropes. This intricate structuring is responsible for the ability of both the individual fibres and the entire stem to resist and sustain bending.

Bamboo has a hierarchical structure that spans many scales and levels of organisation

Remarkably, both changing the conditions of plant growth and subsequent chemical treatment can be used to modify bamboo properties from those typical of wood to those similar to threads used in weaving fabrics for clothing.

What are the current uses of bamboo?

Bamboo has hundreds of uses that include construction, building materials, clothing, toilet paper, single use chopsticks and re-usable coffee cups, furniture, mobile phone cases, fuel, flooring, and food, to name but a few! All of these uses are even more exciting when the fact is considered that bamboo is a cheap, sustainable and renewable resource.

Bamboo has many uses, including being made into re-usable coffee cups

What makes bamboo sustainable?

Bamboo grows very quickly - some varieties by almost 100cm in 24 hours! Taking little time to grow means that more bamboo can be harvested each year than slower growing alternatives. Even the leftover powder and stalks created from the production of other bamboo products can be recycled into fuel pellets as a cheap, green source of energy for home heating systems.

An important benefit is that bamboo can be grown without the use of fertilisers, avoiding detriment to the local environment through waterway and air pollution, as well as acidification and mineral depletion of the soil. Furthermore, bamboo has also been found to be beneficial to the soil. It also prevents soil erosion, i.e. the degradation of the top layer of soil. Planting bamboo in soil found to be dead and fruitless was found to regenerate it for renewed agricultural use.

Bamboo is an eco-friendly alternative to many plastic products and deeply processed paper, and finds structural uses in motorcycle bodies and mobile phone cases. In addition to its ‘green’ production route, bamboo products are biodegradable at the end of their lifetime.

Traditionally, bamboo species are native to warm, tropical climates but have been found in more diverse areas such as highland cloud forests and cool mountainous regions. Many species can grow outside these native habitats, with many found in UK gardens.

In fact, bamboo doesn’t even need to be replanted – cutting a plant down does not kill it, and it regenerates from its own roots! This saves many steps in the production chain and the time to beginning re-growth as soon as possible after harvesting. In comparison, most trees take up to 20 years before they are ready to be cut down. Bamboo captures more carbon dioxide and produces more oxygen than an average hardwood tree.

Bearing all of these factors in mind, it is exciting to think of the possibilities that can come with a further understanding of this incredible plant and ways to adapt it to various applications.

This research is published in Acta Biomaterialia. The MBLEM research laboratory and team in the Department of Engineering Science are headed by Professor Alexander M. Korsunsky. The lab specialises in the combined use of a range of microscopic imaging methods at different scales to elucidate the intricate links between the structure and performance of natural and engineered hierarchically structured materials.

Research Groups

How to help robots learn independently

Robotics