08 Oct 2024

Investigating the behaviour of polymer support fluids for civil-engineering applications

A multi-institution project aims to provide better understanding of the interaction of polymer support fluids with real soils to inform best practice and encourage more widespread and effective use

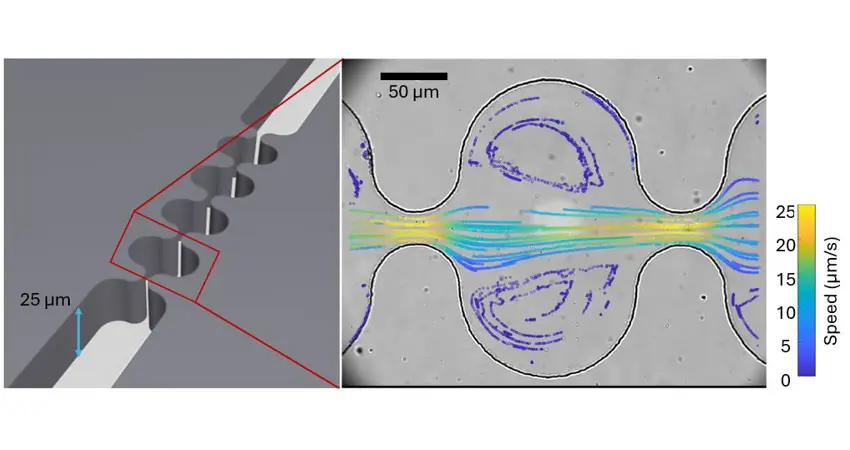

Left: Illustration of a microchannel. The openings and constrictions mimic pores in soil and the throats between them. Right: Image of one “pore” under a microscope. The coloured trails show the paths followed by tracer particles in the fluid. The colour shows how fast the particles are moving as they pass along the channel.

The EPSRC1 -funded “Permeation of Polymer Fluids in Soils” (POPFS) project is investigating the behaviour of polymer support fluids for civil-engineering applications. As the name suggests, support fluids are special fluids that are used to support the walls of an open excavation like a borehole or a trench. Without the support fluid, these excavations would simply cave in during digging.

Traditional support fluids are suspensions of clay particles in water, whereas polymer support fluids are dilute solutions of long polymer chains. Polymer support fluids have a variety of advantages over traditional support fluids in terms of both cost and environmental impact, but they are not yet as widely used as they could be because they are poorly understood.

The POPFS project, a collaboration between researchers at the University of Oxford, Imperial College London, the University of Cambridge, and Environmental Geotechnics Ltd, is designed to provide new insight into how these fluids work – in particular, how they support the walls of an excavation as they seep slowly from the excavation into the surrounding soil. To do this, we need to think on the scale of the microscopic pores in the soil where the fluid and soil grains interact – microns to hundreds of microns – and extrapolate to the scale of an excavation – tens of meters.

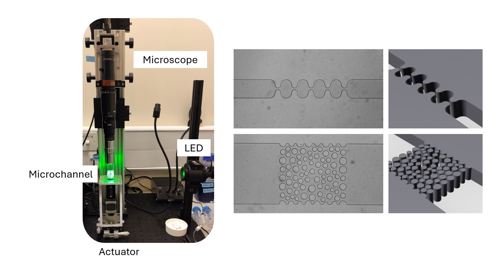

The Poromechanics Lab in Oxford’s Civil Engineering Group has a strong record of using innovative experiments to examine flow and mechanics at the scale of individual grains and pores. In this project, we will investigate the flow within custom microfluidic devices, in which polymer support fluids flow through tiny, artificial pores and channels embedded within blocks of transparent plastic. By adding microscopic tracer particles to the fluid, we can visualise the flow using a custom microscope.

Our collaborators at Imperial College London will perform 3D scans of some representative soils so that we can design microfluidic devices that match real soil pore geometries. They will use our measurements to benchmark their computer models for the flow, which will then be used to predict the forces between the fluid and the soil grains. At the same time, our collaborators at Cambridge University will explore the macroscopic behaviour of different commercial support fluids in sand using laboratory permeameters. In particular, they will leverage advanced imaging techniques to analyse polymer adsorption on soil particles and track polymer movement during testing.

This research is being undertaken with strong support from industry, with representatives from Environmental Geotechnics Ltd, Arup, Keller, and Ward and Burke serving on an advisory panel. Together, the POPFS project will provide a full picture of the interaction of polymer support fluids with real soils. These insights will inform best practice to encourage more widespread and effective use of polymer support fluids, and may inform the design of new support fluids in the future.

1 Engineering and Physical Sciences Research Council