05 Jul 2019

Researchers uncover secrets behind the dynamics of splashing

Splashes are a fact of life, as anyone with children will know. But they’re much more of an issue for inkjet printers, especially when printing circuit boards. For the first time, a team of researchers has identified a way to predict how these splashes will happen – with big implications for the manufacturing sector.

“In technologies such as inkjet, one of the last things you would want is for your drops of ink – particularly the conductive inks used in printed electronics – to disintegrate upon impact, potentially ruining your printed product or even causing short-circuits,” explains Professor Alfonso Castrejon-Pita.

“Similarly, it can cause problems when applying coats by spraying at high speed; potentially valuable material is being lost each time they splash back. As manufacturing is always looking for faster and faster speeds of production, the chances of crossing the 'splashing threshold' is higher and higher.”

Alfonso and his team, including scientists from Cardiff University and Queen Mary University of London, recognised the importance of accurately predicting splashing behaviour. “We have been working on the topic of splashing for a few years now,” he explains. “It’s one of the most challenging topics within the field of microfluidics, as events happen very quickly and at very small scales. Armed with ultra-high speed cameras and high-resolution numerical simulations, we hope to reveal the underlying secrets behind the dynamics of splashing.”

Previously, there were two factors used to explain splashing behaviour: known as Ca and K, these describe the droplet itself (including speed and surface tension), but not how it interacts with the surface it lands on. A universal method for predicting how a droplet would splash was unavailable.

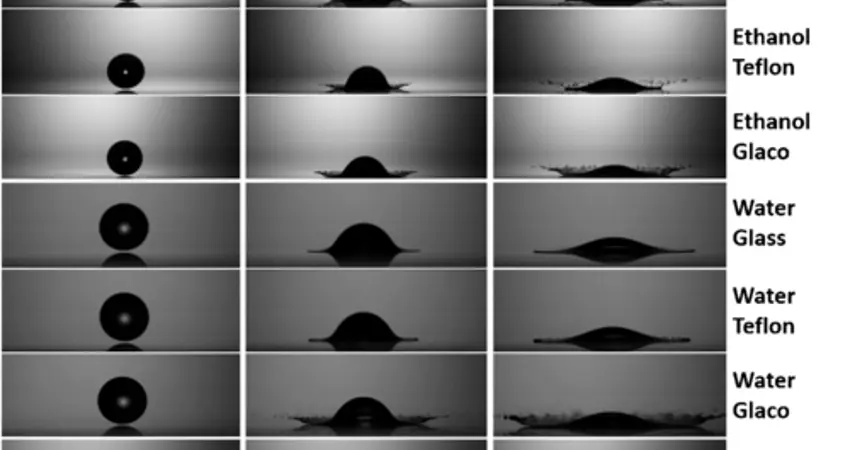

The team made use of ultra-high speed cameras, capable of recording 200,000 frames per second, to watch how three types of droplets performed on impact. They examined water, ethanol and aqueous glycerol (a simple compound often used as a sweetener, chosen because it allowed them to dramatically vary the viscosity of the mixture while hardly modifying other important fluid properties such as surface tension), dropping them onto a range of different surfaces.

They realised that they could predict splashing by noting the contact angle, in conjunction with those Ca and K factors which had previously been determined. However, this varied between liquids; for a universal predictor of splashing behaviour, the researchers would have to look elsewhere.

They found a solution when they combined all these previous considerations with the ‘splashing ratio’. This describes how, when the droplet lands, it spreads out and forms a thin liquid sheet. The leading edge of this sheet lifts off the surface.

With all these factors in mind, the team were able to consistently predict splashes across all three liquids for the first time ever.

And with the success of this study, Alfonso sees further implications ahead. “We believe that the results of this research could be applied to a number of situations in which 'dangerous' or 'nasty' fluids are used,” . It's surprisingly easy to aerosolise droplets – a drop of a typical solvent (like ethanol or methanol) will splash if dropped from a height of about 20cm, and that generates droplets which will be small and light enough to be carried away by air. So if you're working with dangerous chemicals or biological materials, it would be helpful to know that you won't be generating sprays when drops fall, exposing us to diseases or harmful materials. This is also the case with the use of instrument trays during surgery – they could be designed in such a way as to prevent the splash of bodily fluids.

“This could even have an implication in the kitchen. Imagine a drop of contaminated liquid, like water used to wash chicken, hitting a surface at the right speed and splashing - with tiny droplets potentially carrying some of that material away and transmitting food poisoning agents onto your meal.”

Alfonso is an Associate Professor here in the Department, where he established Fluid Dynamics Laboratory. Find out more about his research.