10 Mar 2020

When two become one – the structures created when two droplets combine

Researchers use novel method of observation to explore the delicate science of mixing liquids

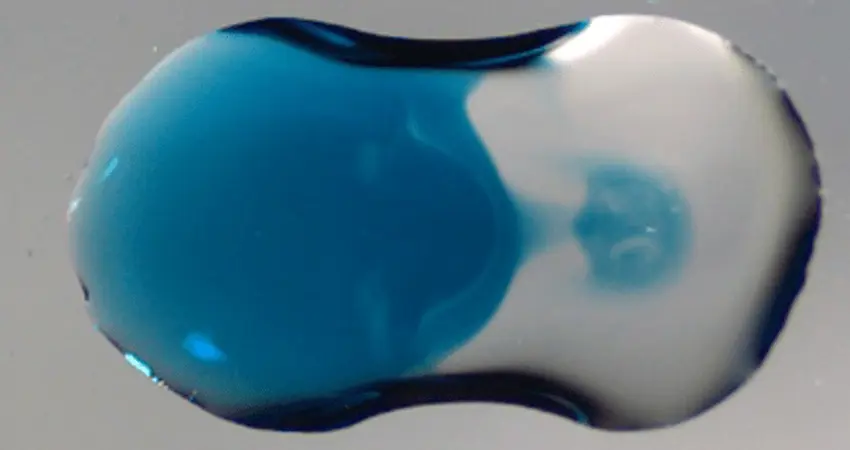

A jet forms between two droplets as they combine.

Engineering researchers have successfully captured the beautiful dynamic structures created when two droplets combine (or “coalesce”) to become one, using high speed cameras. Watching frame by frame, they discovered that varying the properties of the droplets themselves and the distance between them can influence not only the structures created but the degree of mixing and where it takes place.

droplets from below

Two droplets of the same fluid combining as viewed from below. The black bar in the top right corresponds to 1mm scale.

Every aspect of the experiment, carried out at the Oxford Fluid Dynamics laboratory, was performed with delicate precision. A 1.2mm thin glass slide is the base on which the first droplet is dropped onto via the process of dispensing 30 μl (30 millionths of a litre) of the fluid per minute, until the pull of gravity causes the liquid to fall from the dispenser - creating a droplet on a millimetre scale. A second dispenser positioned carefully next to the first one, contains a similar fluid, dyed blue to distinguish it from the first fluid. Waiting for the second drop to fall (the “impacting droplet) are two high speed cameras that capture up to 25,000 frames per second. To put this into context, it takes a mere 24 frames per second for the human eye to perceive a sequence of images as movement. Cameras with such a high frame rate are necessary to capture each stage of the mixing process.

The distance between the droplets, such as whether the “impacting” droplet touches the stationary droplet or the glass slide first, and differing levels of surface tension, were varied to measure their impact on the mixing process. The researchers found that using these precise variations could not only create jets on the surface between the droplets, but also be used to suppress or enhance them. At the forefront of jets, vortices form.

Associate Professor in Fluid Mechanics and co-author of the study, Alfonso Castrejón-Pita explains why these vortices are so important:

“We demonstrate that we can actively enhance mixing by generating vortices on the surface and inside the coalescing droplets upon impact - and vortices are the best thing you can have if you want to mix fluids.”

A vortex is something you may be more familiar with than you think. When you pour milk into your tea or coffee the spiral-like shapes you can see are vortices within your drink - and pulling the plug on your bath creates a vortex as the water spirals down the drain.

This method of observation is a novel one. The majority of studies use one camera, and therefore one viewpoint, to monitor the dynamics of the droplets. However, different viewpoints give distinct advantages. Viewing from the side allows the researchers to see how the falling or “impacting” droplet interacts with the stationary droplet in terms of how deep the mixing goes. Whereas viewing from below shows the shape and structure of the mixing.

side view of droplets

Two droplets of the same fluid combining as viewed from the side. From this viewpoint it is clear that the jet lies on the surface.

Professor Castrejón-Pita adds, “In the past, there have been instances when two droplets impact and you were left wondering whether they have mixed, or has one droplet just passed over the other? Having two cameras record the droplet interaction from different viewpoints answers that question.”

Controlling the mixing of chemicals is important in the field of 3D printing. 3D printers work by depositing chemicals in layers to construct a 3D part. Depending on the part it can be necessary to mix these chemicals together, causing a reaction which results in a solid 3D part. This is done one droplet at a time, and requires the specific properties of the droplets to be tailored to create the desired product.

PhD researcher and lead author of the study Tom Sykes, from the University of Leeds, explains,

“The chemistry behind emerging 3D-printing technologies involves having chemicals deposited onto a surface. We often need those chemicals to be positioned in a highly specific way, for example we may want the droplets to lie side by side or for one droplet to rest on another."

“On other occasions we want them to mix completely, to produce a desired reaction to 3D print more complex structures.”

3D printing already spans a wide range of areas including education, construction, medicine, prototypes and art. The new findings should help to extend the range and type of products that 3D printers can print.

The paper was published in Physical Review Fluids.