13 May 2021

X-rays and Simulations shed light on how fusion reactor armour changes under irradiation

Researchers from the Department of Engineering Science and Culham Centre for Fusion Energy capture the structural evolution of tungsten due to intense irradiation.

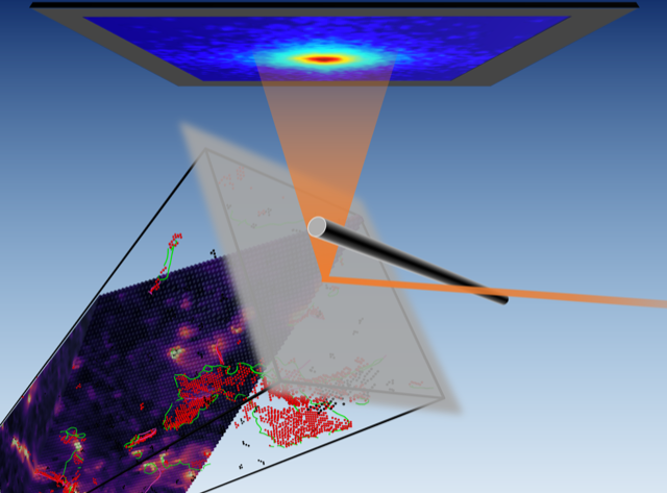

Using synchrotron X-ray micro-diffraction and massive atomistic simulations researchers shed light on the structural changes intense irradiation causes in tungsten armour for future fusion reactors.

Sustainable, low carbon energy production is essential for tackling climate change. Nuclear fusion has the potential to revolutionise the energy sector as a clean and sustainable power source. It occurs naturally inside stars, where the temperatures and pressures are high enough to fuse atoms together, and release energy in the process which we see as starlight. Advances in nuclear fusion reactor design bring this near-limitless energy source ever closer to being a viable power source on earth.

A key hurdle is that high-energy neutrons, which carry the fusion reaction energy, can damage the reactor wall during operation. New materials need to be designed for use as fusion reactor ‘armour’ that can withstand the intense irradiation and very high temperatures involved in the process.

Researchers Dr Suchandrima Das, Dr Hongbing Yu, Mr. David Yang and Professor Felix Hofmann at the Department of Engineering Science, along with colleagues from the Culham Centre for Fusion Energy, have recently conducted a study into tungsten, the main candidate material for fusion armour. The research paper, 'Observation of transient and asymptotic driven structural states of tungsten exposed to radiation', combines x-rays diffraction measurements and large scale atomistic simulations to examine how tungsten changes as a result of high energy particles.

"Our results point to interesting new possibilities for designing more resilient materials with enhanced radiation resistance needed to make fusion power a reality"

Co-author Professor Felix Hofmann explains, “This insight into the delicate interplay of nanoscale defects is very important as tungsten is the main candidate material for fusion armour. Our results point to interesting new possibilities for designing more resilient materials with enhanced radiation resistance needed to make fusion power a reality. For the first time, we managed to capture the full structural evolution of tungsten, due to irradiation, from very low to extremely high doses.”

Remarkably, the kinds of defects formed depend intimately on the amount of radiation the material has been exposed to. Understanding this evolution is essential for gauging how armour components will degrade in service. Lead author, Dr. Daniel Mason, elaborates, “We use X-ray micro diffraction to probe how extreme irradiation changes tungsten, the preferred material for fusion reactor armour. We find that at low doses the tungsten crystal lattice expands, but then seemingly contracts at high damage levels. Using massively parallel atomistic simulations and analyses developed here at the Culham Centre for Fusion Energy, we are able to resolve this puzzling behaviour.”

“Our results show that atoms, knocked from their lattice sites by irradiation, are highly mobile. They quickly orient themselves and self-assemble into new crystal planes, stabilising irreversible swelling. This self-assembly leaves behind vacant lattice sites that cause a contraction of the lattice. Our new research finally enables a linked-up understanding of the mechanisms that control this damage process. “

Detailed understanding of how irradiation changes armour materials is key for the design of future fusion reactors, to predict how components will degrade and evolve in service. It also opens the door to developing new, more radiation resistant materials essential for reliable and cost-effective long-term reactor operation. Designing such new materials is now the focus of the research team’s activities.