Oxford Flow is a spinout company from the Department of Engineering Science that has just celebrated its fifth 5th year in business. Oxford Flow designs and manufactures innovative pressure regulators and valves that improve the efficiency and flow of water, oil and gas. To find out more about this successful spinout company, we spoke to CEO, Neil Poxon.

Oxford Flow was born out of inspiration that came to Professor Tom Povey who, frustrated with what was available while conducting his research on jet engines, created a new standard of pressure regulators and valves. Since that moment, Oxford Flow’s technology is now in use in the water and gas industries and is set to break into the oil and gas market before the end of year.

The products Oxford Flow develop have a much wider range of uses than the initial inspiration from jet engine testing, Neil explains, “The technology that we have developed for flow control is applicable for example, to the hob in your kitchen. Any gas system in your house will be regulated by a flow control device. Imagine if every building, or house in a housing estate, or every office in an industrial complex, all turned on their gas supply at the same time, the valves we develop make sure you have the correct pressure, otherwise it might damage equipment and may even explode!“

“The same is true for water, it doesn’t matter who is using the water, you will always see the same pressure and flow when you turn the tap on. If you expand this concept to a larger scale such as factories and offshore processes, the safety devices they have are the most advanced flow control valves available.”

“The focus is on simplicity and reliability. These types of products have not changed in design or innovation in over 100 years and we have produced something completely different, smaller, lighter, more precise, and reliable. Oxford Flow has created the world’s first polymer valves.” Oxford Flow’s success in designing and commercialising polymer valves led to a significant investment by manufacturing company Georg-Fischer earlier this year.

As well as improving efficiency and reducing costs, Oxford Flow’s technology had unexpected applications linked to conserving water. “Oxford Flow has sold hundreds of valves in the UK, the Middle East and North America, but our biggest customer is actually Mexico.

“I got a call one day out of the blue from a guy in Mexico - we get lots of calls so I said, “If you’re serious you need to come meet with me.” I was on a trip to our America’s headquarter in Houston at the time and he came and met me there. We ended up sending a few valves out and it really mushroomed. It has been very successful.

“Because Mexico has a limited supply of water, most users cannot be guaranteed to have water 100% of the time and so our valves are used to divert water through different parts of the network. Through using our valves to manage network pressures and reduce leakage, they have been able to supply larger portions of the network at any one time so that more customers have water more of the time.”

However, Oxford Flow is going beyond product design, “As well as the mechanical side of our business, we have also developed intelligence around the valves. This is one of the main reasons a company like Georg-Fischer invested in Oxford Flow. We have been working in the Middle East to produce the smartest water distribution network in the world. This is where the industry is going, and everyone is interested in intelligence in smart systems. It includes having a cloud platform to remote control valves, and remote control from customers control rooms. For example, in water utility, we can monitor pressures and temperatures, but also monitor water quality in real-time and send that back to the control room.”

Following their success in utility water, Oxford Flow is going into more markets, “Most of our business to date has been utility water, but we recently just completed a project with SGN (Scottish Gas Networks), for a project in utility gas distribution.”

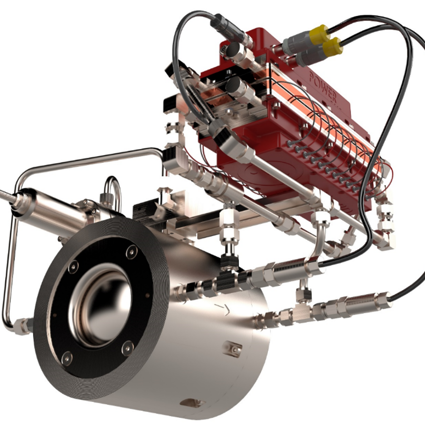

They are also designing valves for the oil and gas industry. A key aspect of their valve design for the oil and gas market is reducing the risk of releasing “fugitive emissions” or hydrocarbons into the atmosphere. This is a key objective for the industry and something that Oxford Flow has been able to achieve through their innovative design which removes the traditional stem component that is subject to leaks. Not only does this benefit companies financially, as resources are not lost, but this has a significant impact on the environment. Fugitive emissions are a source of air pollution and were recorded as contributing 5.2% of world greenhouse gas emissions in 2013.

With their movement into the oil and gas industry, the structure of Oxford Flow has developed to change with their evolving markets. The non-oil and gas side of the company is now in its own subsidiary, a design to help improve the efficiency of the company as the manufacturing side can now be taken over by Georg-Fischer.

In terms of the future, “In the very short term, our biggest market is the US. In places like Mexico, South America, the Middle East, UK and Europe, we can’t go and physically see our customers at the moment. But the US is different, with our America’s headquarters there we are still able to see our customers. We have big expectations for the US. Oxford Flow is hoping that for the next quarter this year, our new subsidiary set up will bring results. We see North America as being the biggest immediate opportunity across all the business.”

Commenting on celebrating their 5th anniversary, Poxon says; “In time we’ve grown from two founders to almost 40 employees. Our product portfolio has expanded significantly from those early days, and we now have solutions for all markets.”.

We look forward to catching up with Oxford Flow and seeing where the next five years takes them.

Student Profile: Tom Commins

DPHIL STUDENT