Tom Commins is a second year DPhil student based at Magdalen College, specialising in the development of materials for body armour. Before his DPhil, Tom studied here for his MEng in Engineering Science, where he worked with Nickel alloys and developed his interest in materials engineering. We spoke to Tom to find out more.

What does your research focus on?

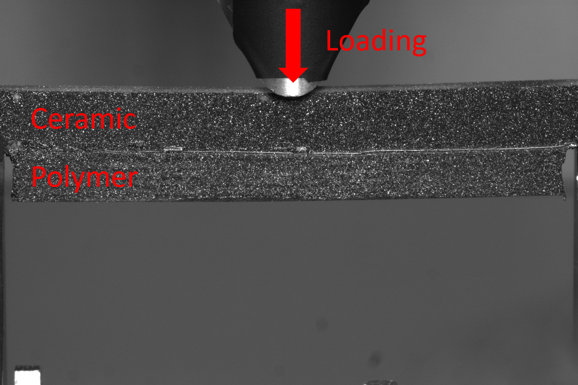

I’m working with composite body armour, which is found in military applications. The armour I’m working on consists of a hard ceramic ‘strike’ face with a soft polymer backing. Essentially, the ceramic is present to provide the hardness to fragment and disrupt the projectile and the polymer is present to absorb energy as it deforms and to help limit the fragmentation of the ceramic. I’m investigating the role of the interface between these two materials and how this can be manipulated to improve future armour design.

Part of my project involves characterising the materials at low loading speeds, creating predictions from these data, and then experimentally testing this. I’ve performed the low rate experiments so recently I have been setting up a gas gun to fire a projectile at my materials to get the low rate data. Like all experimental work, there’s always more set up than you think!

Experimental set up for 3-point bend loading for model composite armour.

How did you get into this topic?

I was interested in materials engineering at the end of my undergraduate and had chosen the supervisor I wanted to work with. After obtaining the DPhil place here, there was a range of projects I could have worked with and this certainly sounded the most interesting.

What is the ‘big picture’ goal for your research?

Essentially, producing a set of ‘guidelines’ of the factors that govern the interface in composite armours and to develop a fundamental understanding as to how the interface affects armour performance. This will help future armours to be developed for better and more efficient protection.

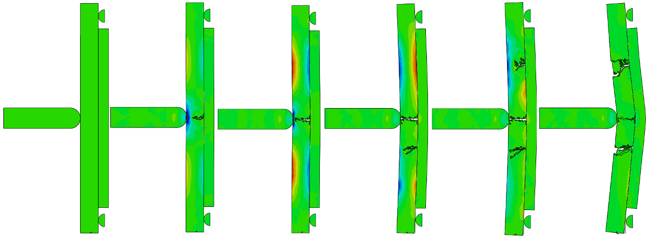

A simulation of a high speed projectile impact into model composite armour.

What is an average day like for you?

My days are relatively varied because my project is a mix of experimental and finite element modelling work. Also ‘average’ day has also lost its meaning because of Covid! I tend to work from home if there’s nothing required of me in the labs, on those days I’ll be developing my finite element model, going through data or designing fixtures for future experiments (of course with a mandatory table tennis match at lunch time). On the days I go into the lab, I’ll be building and setting up fixtures for the equipment, creating composite specimens to test or performing experiments.

What challenges do you face?

The main issue that I’m finding is inter-specimen variability. Ceramics are brittle materials and can fail suddenly, because they’re so brittle there can be significant variation in the failure strength at which they break. This is certainly posing a challenge when looking for trends in data.

What excites you about engineering?

Engineering is the connection between abstract science and the real world. There are a lot of great principals and concepts in science, but it’s engineering that connects it to the real world and turns it into something people can use and improve their lives.

(Thesis aside!) What are your plans for the future?

The future is relatively unplanned at the moment. I’ll most likely begin working as an engineer but where and in what area is undecided and after that we’ll see where it takes me. Although, at the weekends I’m studying to obtain a qualification in sports massage so that’s a good back up if all else fails!

Student Profile : Naomi Mburu

Dphil student