28 Mar 2022

Insight into splashing droplets impacts future engineering in nature and industry

Dr Tom Sykes and Prof Alfonso Castrejon-Pita research the micromechanics of drops splashing on curved surfaces

Droplets splash in various scenarios in nature and in industry, and the understanding of the mechanics of this process is valuable for improving technology in food, aerospace and automotive industries, 3D printing and the impact of natural processes.

While appearances may seem simple, the reality is that the behaviour of droplets is complicated. Professor Alfonso Castrejon-Pita, from the Fluid Dynamics Laboratory at the Department of Engineering Science says, "Drop splashing is a very complex and challenging phenomenon. The exact micromechanics triggering a splash has been the focus of recent studies, but a definitive answer is still missing.”

One of the main factors that affects how a drop splashes is the surface it lands on. Engineers use materials called ‘substrates’ to release droplets onto. A substrate is a substance that another substance is applied to - for example a boulder would be a substrate for moss.

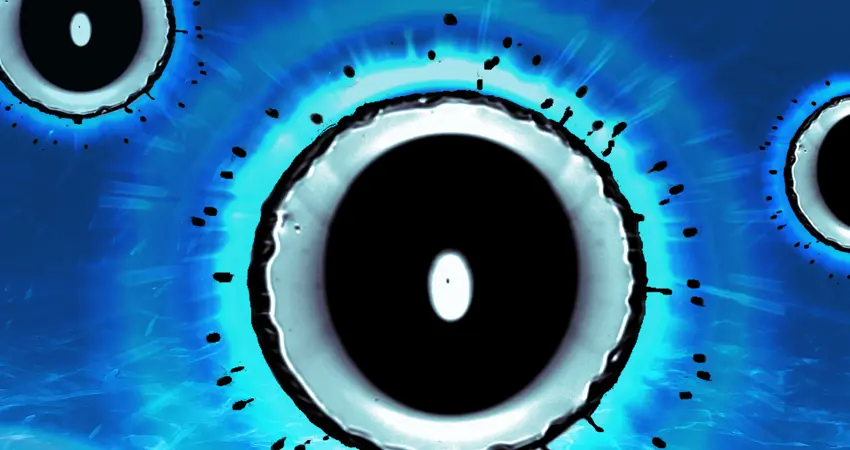

2.07mm diameter ethanol droplet impacting a concave surface (-25.84mm radius of curvature) at 2.22 m/s, filmed from below

So far, one physical type of substrate has been the main focus of research. Dr Tom Sykes, also from the Fluid Dynamics Laboratory, explains, “Droplet splashing on flat substrates is relatively well studied. For flat substrates, there is a mathematical model that predicts relatively well the impact conditions needed for a droplet of given geometry and fluid properties to splash (“splashing threshold”), which has been extended to work with flat substrates of various properties since being introduced in 2014”.

“[Flat substrates] are the ‘easiest’ to study theoretically, numerically, and experimentally”, adds Prof. Castrejon-Pita.

However, real-life scenarios are often more complex and present less regular surfaces for droplets to splash onto. Dr Sykes continues, “Droplet impact on curved substrates is much less well studied; most research looking at impact onto spheres/concave surfaces has focused on droplet spreading following relatively low-speed impact, when splashing is not seen.”

“A small handful of studies have looked at splashing on spheres previously, but generally only on substrates that are to some degree already wet (which affects splashing behaviour greatly). Some of these works present contradictory results on the effect of substrate curvature on splashing thresholds, motivating our comprehensive and conscientious study.”

Their research paper ‘Droplet splashing on curved substrates’ is led by Dr Sykes and co-authored with Engineering Science DPhil student Ben Fudge, Professor Castrejon-Pita and collaborators from the University of Twente and Queen Mary University of London.

“This not only allowed us to explain our results in terms of the underlying physics, but may also enable prediction of splashing thresholds”

Professor Castrejon-Pita tells us, “Here we present the first study where a dry curved substrate is studied, and a simple mathematical model derived to better understand the role that curvature has in modifying the so-called splashing threshold”

The splashing threshold describes at what point a substrate will cause a droplet to splash instead of landing in-tact as one complete drop. For example, pipetting a drop onto a flat surface from a short distance will not splash, but popping a water balloon from a height will.

2.08mm diameter ethanol droplet impacting a 10mm diameter sphere at 2.41 m/s

To capture these properties in detail, the team required advanced technology for high-precision observations as well as a variety of scenarios. Sykes explains, “We let droplets of about 2mm in diameter fall onto a wide range of dry spheres and concave surfaces from different heights, to alter the impact velocity. We imaged the subsequent impact with two high-speed cameras, positioned perpendicularly for the sphere experiments, at up to 100,000 fps [frames per second]”. In comparison, most film and TV shows are recorded at 24 fps.

“We then analysed the resulting videos to determine whether the droplet splashed, whilst also extracting the impacting droplet speed/geometry, and various quantitative data as the droplet spread across the substrate via in-house code.”

Prof Castrejon-Pita tells us, “[Our results] demonstrate that, when a drop hits a substrate, the smaller the radius of curvature of a substrate the less likely it is to splash”. So if you want a drop to splash on a small ball, it will need to travel at a faster speed to splash than for a larger ball. “A similar but inverted trend is observed if impacting onto a concave curved target. A drop will splash easier if it impacts the inside of a spoon, for instance”

"Based on these experimental results, we proposed a modification to a state-of-the-art mathematical model for splashing on flat substrates, to describe the conditions under which droplets splash on spheres and concave surfaces”, adds Sykes.

“Our results provide a potential route to reducing droplet splashing in applications without changing the droplet properties”

“This not only allowed us to explain our results in terms of the underlying physics, but may also enable prediction of splashing thresholds for different substrate/droplet combinations”. An important factor for the wider application of this research. Whether or not a droplet splashes, and being able to control that behaviour, can have big consequences across many industries.

Sykes expands “Lots of processes see droplets impacting spherical particles, including spray drying (a process used to create fine powders for foods, pharmaceuticals and more), rain-induced icing events, and additive manufacturing. Understanding collision outcomes and subsequent dynamics is very important here”

The research paper made the inside cover of the Journal of Colloid and Interface Science, Vol. 615

“Additionally, inkjet printing applications where tiny droplets are precisely deposited to build up patterns, such as printed circuit boards or biosensors, are expanding into texture surface markets like the food, aerospace and automotive industries. Splashing is usually bad news in these applications, as it affects finish quality and can even ruin products (e.g. short-circuiting printed circuit boards), so understanding when and why splashing occurs is very important.”

“Based on our results, it’s possible to imagine engineered surfaces that feature repeated convex structures to reduce splashing and subsequent aerosolization of potentially-hazardous fluids.”

A key aspect is that by understanding how droplets interact with different shapes of substrates, the drops themselves do not need to be changed. Sykes concludes, “Our results provide a potential route to reducing droplet splashing in applications without changing the droplet properties. They also improve our fundamental understanding of the micromechanics splashing on solid substrates in general, especially though our modification to the mathematical model originally derived for flat substrates.”

Their research paper is also available to view for free on Dr Sykes' website.